Press-in technique

The SMP Series

The press-in units of the SMP series are specifically designed for compressive forces and stand out thanks to their robust, low-maintenance construction. Their straightforward design makes them ideal for use in harsh industrial environments.

The digital force sensor is positioned close to the plunger; stroke measurement is performed via an absolute measurement system.

In combination with the MultiPro 3G control system, high-precision force transducers and exact position detection enable reliable assembly – with complete documentation of all process data.

The SMP series provides a powerful system for quality-critical press-in applications.

Technical Features at a Glance:

-

Maintenance-free servo motor for long-lasting and reliable operation

-

High repeatability for consistent process quality

-

Compact design with offset drive

-

Robust housing made of stainless steel and aluminum

-

Resistant to electromagnetic interference thanks to digital data transmission

Select a Series

for More Information:

0.05 – 2.0 kN (4 versions)

1 – 5 kN (2 versions)

4 – 70 kN (4 versions)

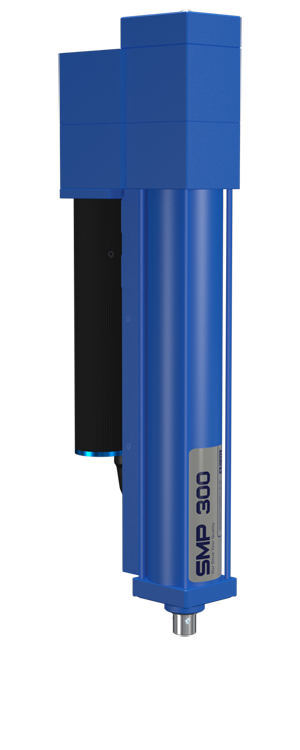

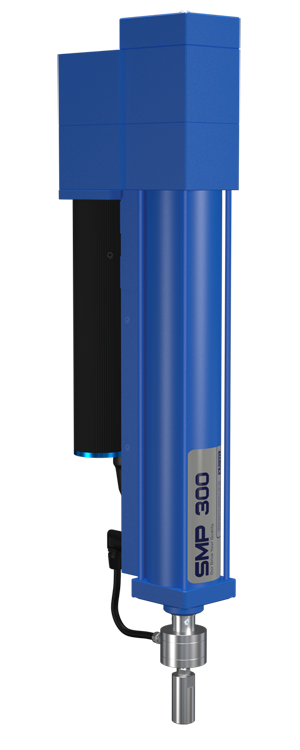

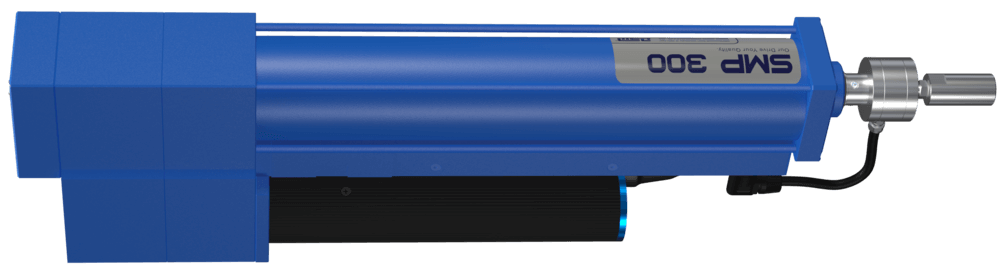

SMP 300 Series

Press-in unit with brushless, electronically controlled servo motor, digital force sensor and absolute stroke measurement system.

The SMP-300 series is available in a basic design with a stroke of 100 mm, 200 mm or 400 mm. Available nominal forces: 0.25 kN, 0.5 kN, 1 kN, and 2 kN in DR version (compression).

Features

- Servo motor, motor attachment angled via motor offset for compact design

- Force sensor direct-acting, installed on the plunger

- Precision of force measurement 1% of the final value

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

- Stamping speed max. 350 mm/s in both directions continuously variable

Force Ranges

-

SMP 300 / 0025*: 0.05 to 0.25 kN

-

SMP 300 / 005*: 0.1 to 0.5 kN

-

SMP 300 / 01: 0.2 to 1 kN

-

SMP 300 / 02: 0.4 to 2 kN

* with externally mounted digital force sensor

Accessories

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set

Weights

-

With 100 mm stroke: approx. 6.5 kg

-

With 200 mm stroke: approx. 7.5 kg

-

With 400 mm stroke: approx. 9.0 kg

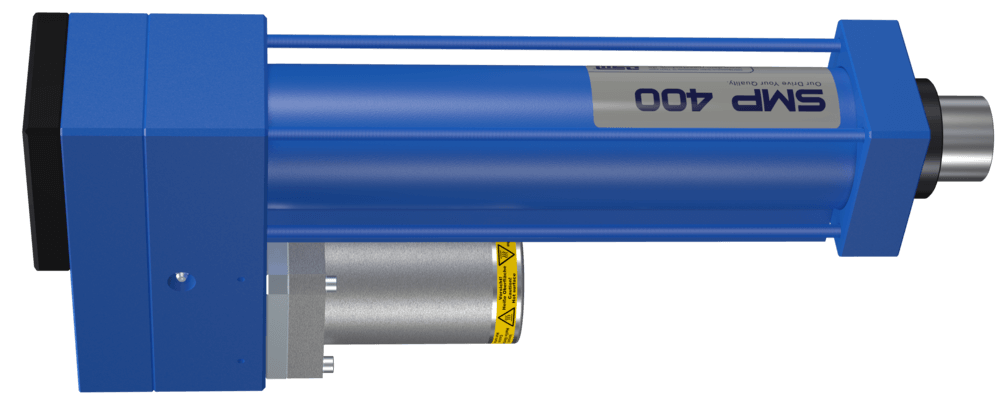

SMP 400 Series

Press-in unit with brushless, electronically controlled servo motor, digital force sensor and absolute stroke measurement system.

The SMP-400 series is available in a basic design with a stroke of 100 mm, 200 mm or 400 mm. Available nominal forces: 5 kN and 10 kN in DR version (compression).

Features

- Servo motor, motor attachment angled via drive offset for compact design

- Force sensor direct-acting, installed on the joint plunger

- Precision of force measurement 1% of the final value

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

- Stamping speed max. 250 mm/s in both directions continuously variable

Force Ranges

-

SMP 400 /05: 1 to 5 kN

-

SMP 400 / 10: 2 to 10 kN

Standard options

- Motor holding brake for higher tool weight

Accessories

- Fan unit for cooling the motor

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set

Weights

-

With 100 mm stroke: approx. 22 kg

-

With 200 mm stroke: approx. 24 kg

-

With 400 mm stroke: approx. 30 kg

SMP 500 Series

Press-in unit with brushless, electronically controlled servo motor, digital force sensor and absolute stroke measurement system.

The SMP-500 series is available in a basic design with a stroke of 100 mm, 200 mm or 400 mm stroke. Available nominal forces: 20 kN, 30 kN, 50 kN, and 70 kN in DR version (compression).

Features

- Servo motor, motor attachment angled via drive offset for compact design

- Force sensor direct-acting, installed on the plunger

- Precision of force measurement 1% of the final value

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

- Stamping speed max. 150 mm/s in both directions continuously variable

Force Ranges

-

SMP 500 / 20: 4 to 20 kN

-

SMP 500 / 30: 6 to 30 kN

- SMP 500 / 50: 10 to 50 kN

- SMP 500 / 70: 14 to 70 kN

Standard options

- Motor holding brake for higher tool weight

Accessories

- Fan unit for cooling the motor

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set

Weights

-

With 100 mm stroke: approx. 100 kg

-

With 200 mm stroke: approx. 120 kg

-

With 400 mm stroke: approx. 150 kg