Manual Workstation

XMP BenchPressUnit

DSM offers modular complete systems for customized individual workstation solutions. Whether as a standalone unit for the workbench, with a base frame, or as a height-adjustable version – the XMP BenchPressUnit adapts flexibly to your production requirements. All versions are optionally available with an electrically locked lifting door or safety light curtain.

Instantly ready — easy to operate with integrated DSM press-in technology, comprehensive process documentation, and smart data communication.

The BenchPressUnit is designed for the powerful press-in units of the XMP series:

⟶ XMP 60 series (0.5 / 1 / 2 kN) and XMP 90 series (5 / 12.5 / 25 kN)

⟶ Optional multi-range calibration for several force rangese

This ensures the right force range is available for every application.

For more details on equipment, variants, control, and safety, please refer to the technical insights.

The XMP BenchPressUnit, featuring a 200 mm stroke, is a compact and modular manual workstation designed for small-batch production, testing applications, and sample or prototype assembly. With powerful configurations ranging from 0.1 to 25 kN and integrated safety features in accordance with Performance Level E, it enables efficient and reliable press-in processes.

The integrated MultiPro 3G control system provides intelligent press-in strategies and advanced functions to support your specific requirements and custom process solutions.

Precision & Safety

-

The system offers two safety solutions for maximum operator protection: an electrically locked lifting door that prevents access during the process and opens automatically only after release, or a vertically aligned safety light curtain (ESPE) that reliably detects any intrusion into the working area and immediately stops the process

-

Two integrated signal lights clearly visualize the process status (OK, NOK, RUN)

-

Flexible force ranges from 0.1 to 25 kN with optional multi-range calibration for changing press-in requirements

-

Compact design with all electronic components including safety PLC – no external control cabinet required

Modular Design & Configurations

-

Available as a standalone bench-top unit, with base frame, or in a height-adjustable version

-

Plunger stroke range : 200 mm – ideal for components and workpieces of varying heights

-

Interchangeable clamping plate with T‑slot and centring bore, optionally customised to your workpiece fixture

-

Compatible with press-in units of the XMP 60 series (0.5 / 1 / 2 kN) and XMP 90 series (5 / 12.5 / 25 kN)

-

Perfect for small-batch production, testing applications, and prototype construction

-

Turnkey delivery – individually tailored to your process requirements

Integrated Control System

-

Control of product-specific sequences via the integrated MultiPro 3G, covering all process steps – multiple programs can be initiated

-

Process monitoring: Recording of force, stroke, and time profiles with complete data logging for quality documentation

-

Smart data communication: Industrial interfaces (including OPC UA, Profinet, EtherCAT) enable seamless integration into MES and plant management systems

-

Optional: 8″–19″ Windows tablet with MPEC software for advanced process control, operator guidance, and analysis – side-mounted and swivelable for optimal ergonomics

-

Operator panel mounted on the BenchPressUnit with buttons for emergency stop, acknowledgment, start, NOK reset, and process-specific functions – removable and ergonomically positionable

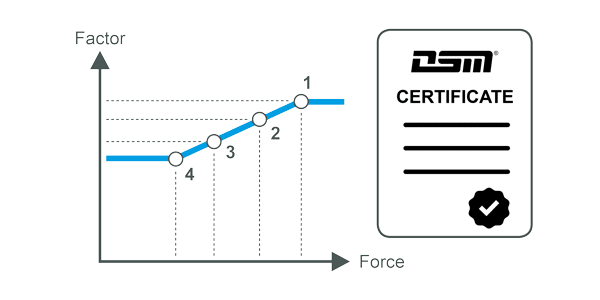

Multi-Range Calibration

With the optional multi-range calibration, you can flexibly use your press-in unit for applications with varying force requirements – while maintaining consistently high measurement accuracy.

Especially for frequently changing processes or component variants, calibration across multiple defined measurement points ensures reliable and precise results throughout the entire force range.

🔧 How it works:

Up to five measurement points are defined via a calibration series using a reference transducer. This allows force measurement to be specifically adjusted to different force levels within the press-in unit’s operating range – for maximum precision from low to high forces.

The XMP BenchPressUnit with electrically locked lifting door combines maximum safety with ergonomic operation.

During the press-in process, access to the work area remains securely locked – the lifting door only opens automatically after release. This version is ideal for applications requiring a high level of protection. Together with the integrated safety features and compact design, it creates an efficient manual workstation that meets the highest standards of safety and user comfort.

XMP BenchPressUnit Base

- Design: Without base frame, with four leveling feet

- Function: Fully equipped with press-in technology and electrically locked safety door

- Dimensions (W × D × H): approx. 387 × 518 × 960 mm

- Weight: approx. 250 kg

XMP BenchPressUnit Frame

- Design: Standard workbench with flush-mounted clamping plate

- Function: Fully equipped with press-in technology and electrically locked safety door

- Dimensions (W × D × H): approx. 800 × 800 × 1780 mm

- Table height: approx. 950 mm

- Weight: approx. 350 kg

XMP BenchPressUnit Flex

- Design: Height-adjustable table with flush-mounted clamping plate

- Function: Fully equipped with press-in technology and electrically locked safety door

- Dimensions (W × D × H): approx. 800 × 800 × max. 1985 mm

- Table height: retracted approx. 755 mm, extended approx. 1155 mm

- Weight: approx. 350 kg

The XMP BenchPressUnit with contactless protective device (ESPE) combines high safety with maximum efficiency.

A vertically positioned safety light curtain at the front monitors access to the working area – if the protective field is interrupted during the process, the integrated safety PLC immediately stops the system.

Since no safety door needs to be opened, this variant enables especially fast, tool-free access.

Ideal for processes with frequent workpiece changes, where short setup times and ergonomic operation are essential. Its compact design, combined with integrated safety functions, makes it a reliable solution for demanding applications.

XMP BenchPressUnit OpenFrame

- Design: Standard workbench with flush-mounted clamping plate

- Function: Fully equipped with press-in technology and safety light curtain

- Dimensions (W × D × H): approx. 800 × 800 × 1950 mm

- Table height: approx. 950 mm

- Weight: approx. 380 kg

XMP BenchPressUnit OpenFlex

- Design: Height-adjustable table with flush-mounted clamping plate

- Function: Fully equipped with press-in technology and safety light curtain

- Dimensions (W × D × H): approx. 800 × 800 × max. 2155 mm

- Table height: retracted approx. 755 mm, extended approx. 1155 mm

- Weight: approx. 380 kg