Service

Consultation by DSM

The earlier DSM is involved in your project, the better the results. With in-depth expertise, we identify and analyze specific needs and requirements – providing you with competent and targeted advice.

Whether it’s special applications, tightening, press-in or testing processes, safety aspects, tool configuration, external sensors, measuring devices, feeding technology, or the equipment of workstations and systems – all factors must be optimally coordinated to ensure perfect results.

This is how your idea becomes a reliable process – with our support.

Compact Expertise

The DSM Journal offers technical articles on tightening and press-fit technology – covering fundamentals and functions, a torque table for tightening torques, and aspects of quality assurance. Compact, practical, and helpful for planning your project.

Select a topic area

This will give you targeted information about our technologies.

Whether for serial applications, demanding special applications, or testing processes – DSM provides the right technology for complex tightening and testing tasks.

Excerpt of realized solutions:

- Tightening to head contact

- Automated thread testing > find out more

- Tightening with self-tapping screws

- Detection of thread entry

- Radial play and bending moment testing

- Screw break detection

- Envelope curve monitoring

- Stick-Slip detection

- Redundant measuring circuit

- Sheet metal fastening and special fasteners (e.g., micro-encapsulated screws, stop and crimp nuts)

- Shutdown based on external target values (sensor) with torque and angle monitoring

Result: maximum quality and process reliability – even for demanding applications.

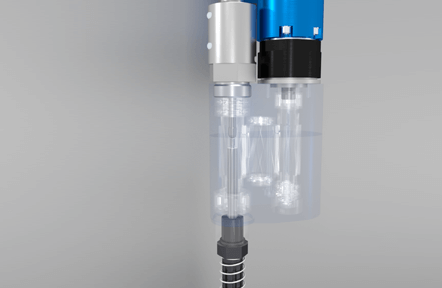

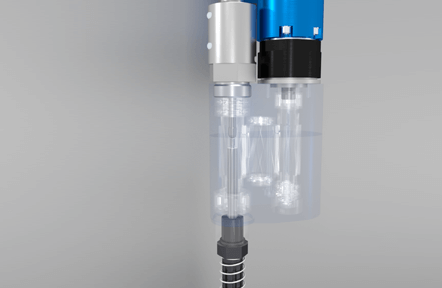

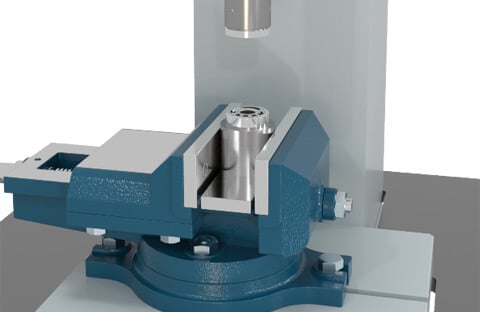

DSM offers advanced technology for precise press-in processes – and much more: force- and displacement-controlled testing can also be realized using the same technology.

Selected features at a glance:

- Holding force/position for a defined period of time

- Force linearization for multi-range calibration

- Length linearization to compensate for elastic components in the process

- Friction coefficient determination to ensure process quality

- Differential force monitoring for high accuracy in connections

- Integration of external sensors for enhanced process analysis

- Envelope curve monitoring for evaluating the press-in process

- Redundant data recording

- Clip point detection for monitoring fasteners

- Review stroke for analyzing process sequences

Result: maximum precision and reliability – even in sensitive press-in and testing processes.

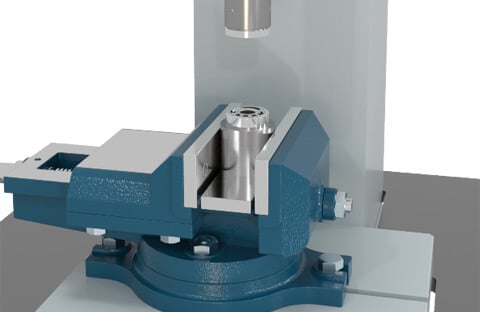

Whether manual workstation or fully automated station – DSM offers well-thought-out solutions for assembly, testing, and diagnostics.

We develop complete workstations for tightening, press-in, and testing applications, or supply the right technology as a system partner for complex automation projects. Always with the same goal: reliable processes and top quality.

Examples from our range of applications:

- Complete solutions for manual workstations – including for testing and diagnostics

- Fully automated assembly and testing stations using DSM technology

- Integration into robot cells and production lines

- Handling systems with position monitoring

- Automated testing with documented results

- Interfaces to higher-level systems

- Scalable control solutions for various plant concepts

- Feed units with nozzle for screws or joining parts – custom-adaptable

Result: efficient automation with adaptable technology – tailored precisely to your processes.

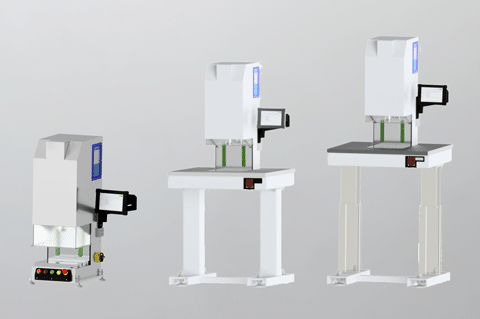

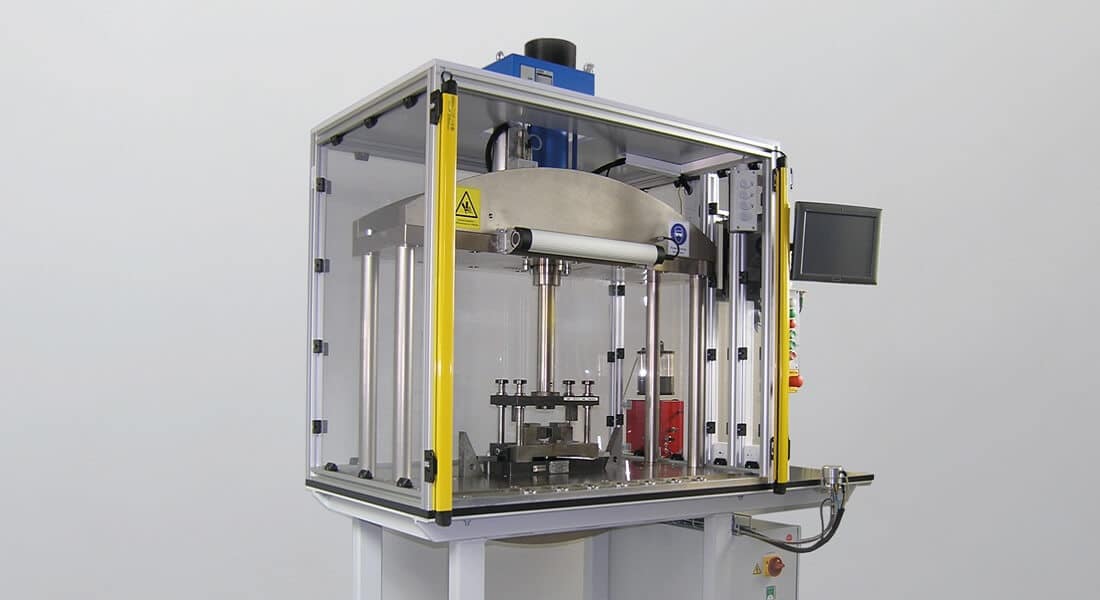

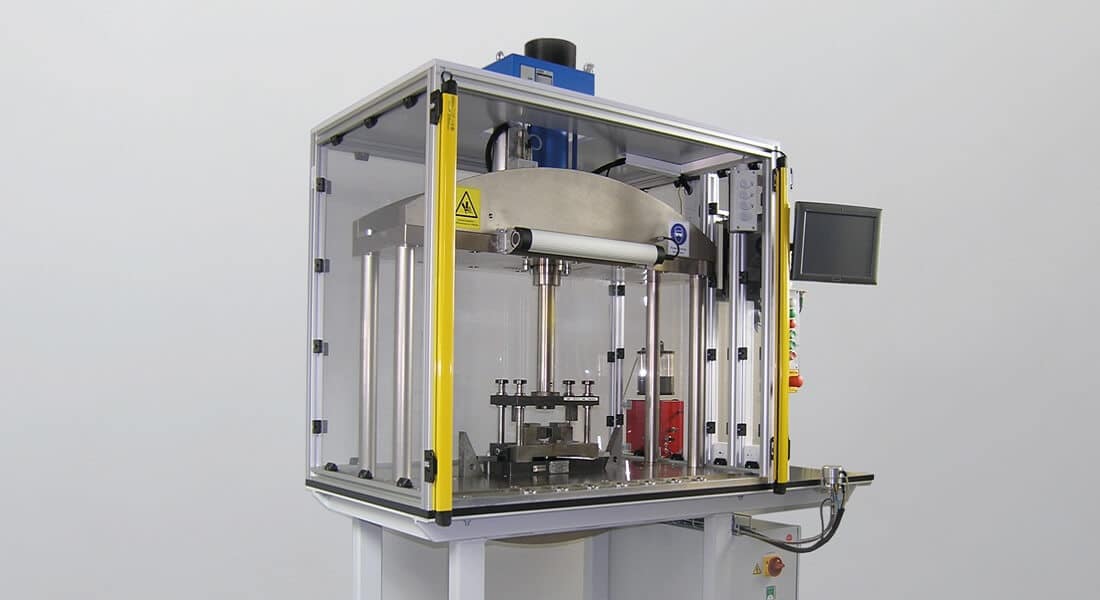

Modular Series Product: XMP-TischPressZelle

The compact station combines our high-performance XMP press-in unit with an ergonomic manual workstation.

Modular and turnkey – tailored to your requirements and individual process solutions.