Tightening technique

Built-In Nutrunners – DS Series

Error-free processes are the foundation of high-quality products – especially in industrial manufacturing, where reliability is the highest priority.

Screw connections must not become a weak point.

To prevent errors from occurring in the first place, DSM’s digitally controlled built-in nutrunners ensure consistently high quality and maximum process reliability.

All DSM products can be seamlessly integrated into new or existing production lines – delivering tailored solutions for stationary tightening technology.

Our experts support you from planning and commissioning all the way to long-term assistance during ongoing operation – competent, practical, and reliable.

Stationary Tightening Technology by DSM

- Digital tightening systems for integration into assembly lines

- Built-in nutrunners from 0.05 Nm to 2400 Nm

- Error-free setup through integrated parameter memory

- Maintenance-free, brushless servo motor with clockwise / counterclockwise rotation

- Robust housing made of stainless steel and aluminium

- Flexible use thanks to a wide range of drive and output variants

Accessories for DS Built-in Nutrunners

Expand your application possibilities with proven accessories for stationary tightening technology: crowfoot gear units, tool change boxes, handling systems, as well as customized technical solutions on request.

Our portfolio also includes complete workstations – from ergonomic manual workstations to semi-automated solutions.

▶ What’s the Right Torque for Your Application?

Our “Bolt Tightening Torque Chart” provides tips and typical reference values for standard metric threads – a practical guide for selecting the right nutrunner.

Select a Series

for More Information:

0.05 – 4 Nm (4 versions)

0.5 – 15 Nm (4 versions)

0.5 – 35 Nm (5 versions)

5 – 140 Nm (5 versions)

44 – 600 Nm (5 versions)

180 – 2400 Nm (5 versions)

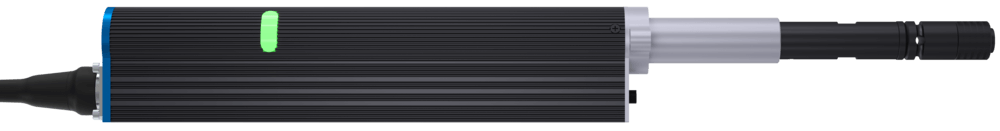

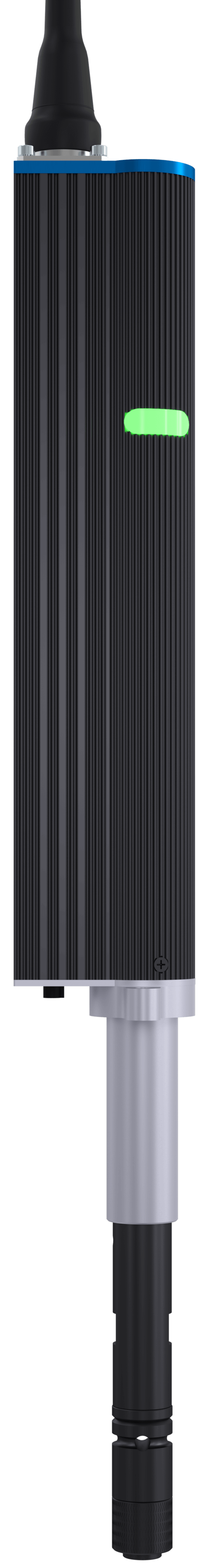

Built-in nutrunner with electronically controlled servo motor and digital data transmission.

The DS-26 series is available in 0.5 Nm, 1 Nm, 2 Nm, and 4 Nm versions – either as MDW type (with digital torque sensor) or as current-controlled SA type.

Standard Equipment:

- Status indication via light field

- Plug-and-play parameter transmission

- Motor and gearbox integrated in an aluminum housing

- Continuously adjustable speed, clockwise / counterclockwise rotation

- Fixed, without output – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via motor sensors

- Angle resolution: 3.7° (DS26/005, 26/01); 2.6° (DS26/02);

1.0° (DS26/04)

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 4.3° (DS26/005, 26/01); 2.1° (DS26/02);

1.0° (DS26/04) - Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Versions | Torque Range | Speed (MDW) | Speed (SA) |

|---|---|---|---|

| DS 26 / 005 | 0.05 – 0.5 Nm | 1450 1/min | 1700 1/min |

| DS 26 / 01 | 0.2 – 1 Nm | 1450 1/min | 1700 1/min |

| DS 26 / 02 | 0.4 – 2 Nm | 1020 1/min | 820 1/min |

| DS 26 / 04 | 0.8 – 4 Nm | 400 1/min | 400 1/min |

Standard Options

- Mounting flange

- Direct output variant (without spring deflection)

- Spring output with 20 mm or 50 mm spring deflection

- Self start output with 5 mm spring deflection – tightening process starts automatically when compressed

- Output offset (displaced output) with 20 mm spring deflection – reduces center distance and improves accessibility in confined screw locations

- Angle head with DIN 3126 D6.3 quick-change chuck

- Vacuum screw holder

- Output unit with galvanic isolation

- Output features (1/4″ hex/square, quick-change chuck B3/B5.5/D6.3) – depending on configuration, compatible with spring output, self-start output, or output offset

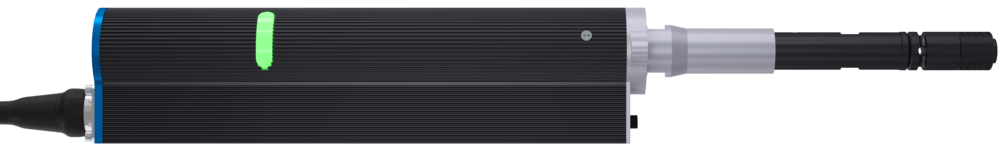

Built-in nutrunner with electronically controlled servo motor and digital data transmission.

The DS-34 series is available in 2.5 Nm, 5 Nm, 10 Nm, and 15 Nm versions – either as MDW type (with digital torque sensor) or as current-controlled SA type.

Standard Equipment:

- Status indication via light field

- Plug-and-play parameter transmission

- Motor and gearbox integrated in an aluminum housing

- Continuously adjustable speed, clockwise / counterclockwise rotation

- Fixed, without output – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via digital absolute encoder

- Angle resolution: 0.1°

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 3.3° (DS34/025, 34/05); 1.7° (DS34/10, 34/15)

- Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DS 34 / 025 MDW | 0.5 – 2.5 Nm | 880 1/min |

| DS 34 / 05 MDW or SA | 1 – 5 Nm | 880 1/min |

| DS 34 / 10 MDW or SA | 2 – 10 Nm | 1540 1/min |

| DS 34 / 15 MDW or SA | 3 – 15 Nm | 1540 1/min |

Standard Options

- Mounting flange

- Direct output variant (without spring deflection)

- Spring output with 30 mm or 50 mm spring deflection

- Self start output with 30 mm or 50 mm spring deflection – tightening process starts automatically when compressed

- Output offset (displaced output) – reduces center distance and improves accessibility in confined screw locations

- Angle head with DIN 3121 F10 3/8“ male square drive

- Output unit with galvanic isolation

- Output features (1/4″ / 3/8″ square drive, D6.3–24 mm quick-change chuck) – compatible with direct mounting as well as with spring output, self-start output, and output offset

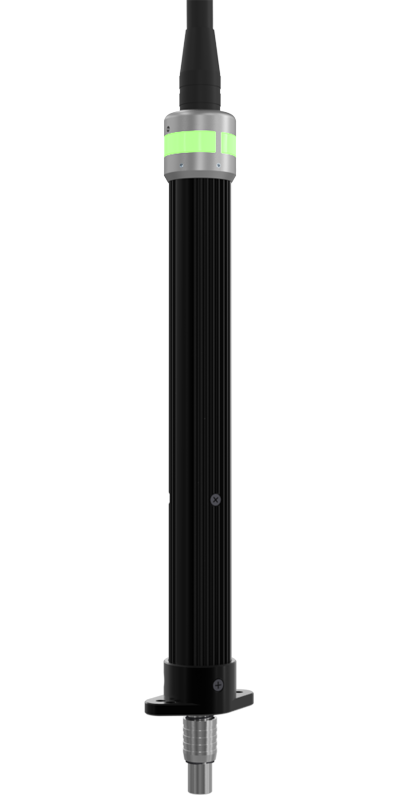

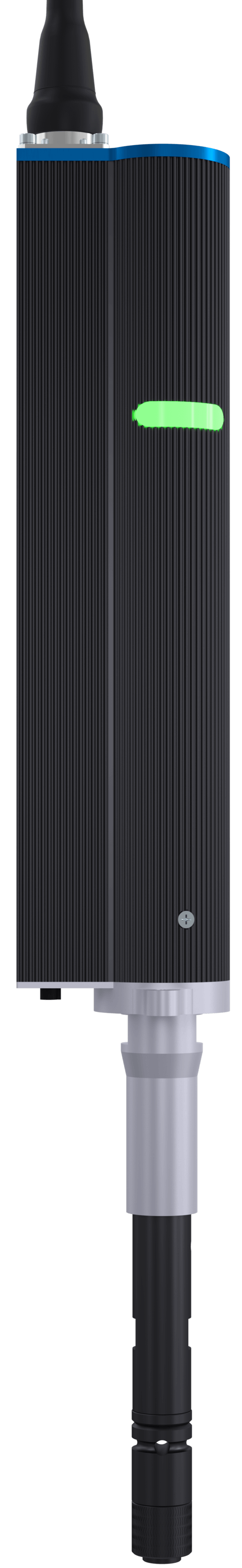

Built-in nutrunner with electronically controlled servo motor and digital data transmission.

The DS-44 series is available in 2.5 Nm, 5 Nm, 10 Nm, 20 Nm, and 35 Nm versions – either as MDW type (with digital torque sensor) or as current-controlled SA type.

Standard Equipment:

- Status indication via light field

- Plug-and-play parameter transmission

- Motor and gearbox integrated in an aluminum housing

- Continuously adjustable speed, clockwise / counterclockwise rotation

- Fixed, without output – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via digital absolute encoder

- Angle resolution: 0.1°

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 3.3° (DS44/05); 2.3° (DS44/10); 1.4° (DS44/20);

1.0° (DS44/35) - Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DS 44 / 025 MDW | 0.5 – 2.5 Nm | 1300 1/min |

| DS 44 / 05 MDW or SA | 1 – 5 Nm | 1300 1/min |

| DS 44 / 10 MDW or SA | 2 – 10 Nm | 900 1/min |

| DS 44 / 20 MDW or SA | 4 – 20 Nm | 530 1/min |

| DS 44 / 35 MDW or SA | 7 – 35 Nm | 480 1/min |

Standard Options

- Mounting flange

- Direct output variant (without spring deflection)

- Spring output with 30 mm or 50 mm spring deflection

- Self start output – tightening process starts automatically when compressed

- Output offset (displaced output) – reduces center distance and improves accessibility in confined screw locations

- Angle head with DIN 3121 F10 3/8“ male square drive

- Output unit with galvanic isolation

- Output features (1/4″ / 3/8″ square drive, D6.3–24 mm quick-change chuck) – compatible with direct mounting as well as with spring output, self-start output, and output offset

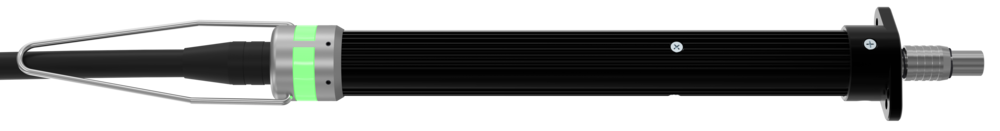

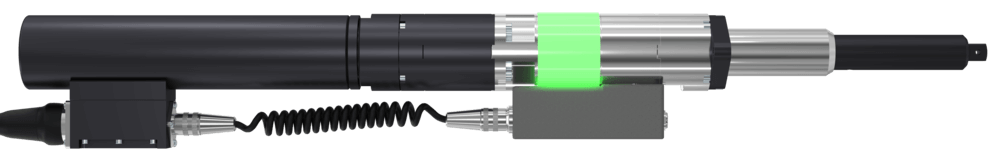

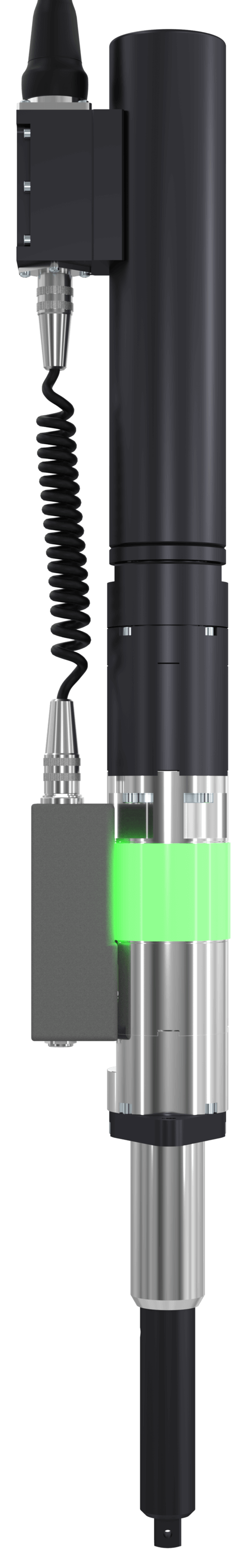

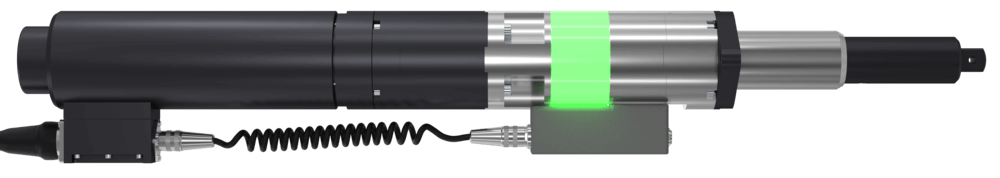

Built-in nutrunner with electronically controlled servo motor and digital data transmission.

The DS-57 series is available in 25 Nm, 50 Nm, 70 Nm, 90 Nm, and 140 Nm versions – either as MDW type (with digital torque sensor) or as current-controlled SA type.

Standard Equipment:

- Status indication via light field

- Plug-and-play parameter transmission

- Continuously adjustable speed, clockwise / counterclockwise rotation

- Compact design

- Fixed, without output

- Motor and output variants – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via digital absolute encoder

- Angle resolution: 0.1°

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 4.5° (DS57/25, 57/50);

2.2° (DS57/70); 1.2° (DS57/140) - Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DS 57 / 25 MDW | 5 – 25 Nm | 650 1/min |

| DS 57 / 50 MDW or SA | 10 – 50 Nm | 800 1/min |

| DS 57 / 70 MDW or SA | 14 – 70 Nm | 800 1/min |

| DS 57 / 90 MDW | 18 – 90 Nm | 430 1/min |

| DS 57 / 140 MDW or SA | 28 – 140 Nm | 430 1/min |

Standard Options

- Motor Offset – side-mounted motor for a more compact design and shorter installation length

- Mounting flange

- Direct output variant (without spring deflection)

- Spring output with 50 mm or 100 mm spring deflection, available with 3/8″ or 1/2″ square drive

- Self-start output with 50 mm spring deflection and 3/8″ or 1/2″ square drive – tightening process starts automatically when compressed

- Output offset (displaced output) – reduces center distance and improves accessibility in confined screw locations

- Angle head with 1/2“ male square drive

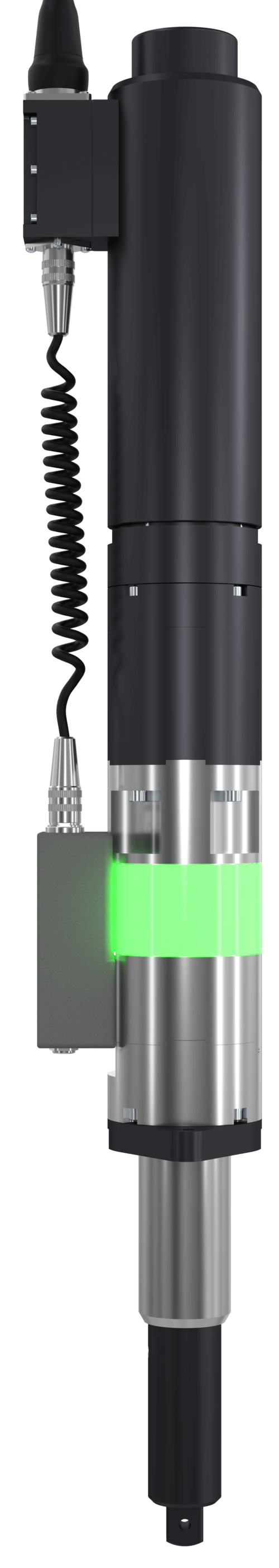

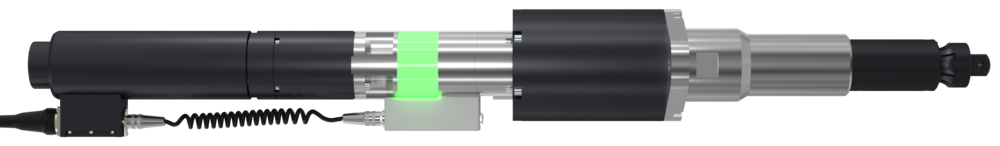

Built-in nutrunner with electronically controlled servo motor and digital data transmission.

The DS-80 series is available in 220 Nm, 300 Nm, 420 Nm, 500 Nm, and 600 Nm versions – either as MDW type (with digital torque sensor) or as current-controlled SA type.

Standard Equipment:

- Status indication via light field

- Plug-and-play parameter transmission

- Continuously adjustable speed, clockwise / counterclockwise rotation

- Compact design

- Fixed, without output

- Motor and output variants – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via digital absolute encoder

- Angle resolution: 0.1°

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 1.2° (DS80/220, 80/300);

1.0° (DS80/420, 80/500, 80/600) - Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DS 80 / 220 MDW or SA | 44 – 220 Nm | 320 1/min |

| DS 80 / 300 MDW or SA | 60 – 300 Nm | 320 1/min |

| DS 80 / 420 MDW or SA | 84 – 420 Nm | 160 1/min |

| DS 80 / 500 MDW or SA | 100 – 500 Nm | 160 1/min |

| DS 80 / 600 MDW or SA | 120 – 600 Nm | 160 1/min |

Standard Options

- Motor Offset – side-mounted motor for a more compact design and shorter installation length

- Mounting flange

- Direct output variant (without spring deflection)

- Spring output with 50 mm, 100 mm, or 150 mm spring deflection and 3/4″ square drive

- Self-start output with 50 mm, 100 mm, or 150 mm spring deflection and 3/4″ square drive – tightening process starts automatically when compressed

- Output offset (displaced output) – reduces center distance and improves accessibility in confined screw locations

- Output offset available in two versions: with direct output (1″ square drive) or with 50 mm spring deflection and 3/4″ square drive

- Angle head (max. 220 Nm) with DIN 3121 F20 3/4“ male square drive

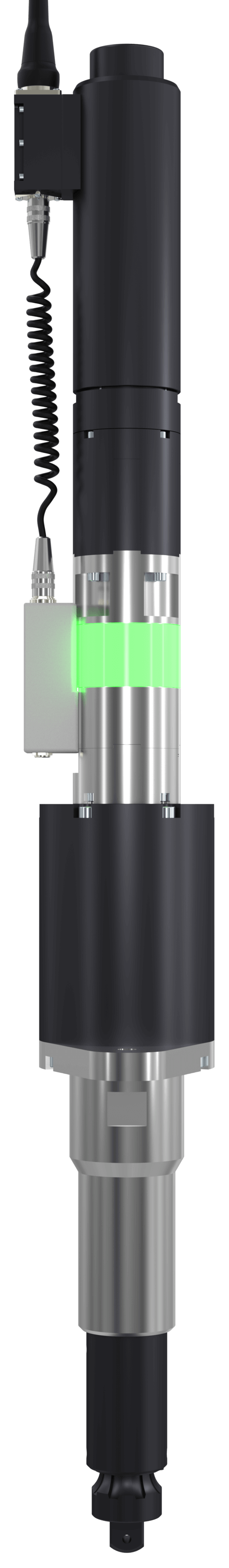

Built-in nutrunner with electronically controlled servo motor and digital data transmission.

The DS-80–130 series is available in 900 Nm, 1000 Nm, 1500 Nm, 2000 Nm, and 2400 Nm versions – either as MDW type (with digital torque sensor) or as current-controlled SA type.

Standard Equipment:

- Status indication via light field

- Plug-and-play parameter transmission

- Continuously adjustable speed, clockwise / counterclockwise rotation

- Compact design

- Fixed, without output

- Motor and output variants – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via digital absolute encoder

- Angle resolution: 0.1°

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 1.0°

- Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DS 80–130 / 900 MDW or SA | 180 – 900 Nm | 75 1/min |

| DS 80–130 / 1000 MDW or SA | 200 – 1000 Nm | 75 1/min |

| DS 80–130 / 1500 MDW or SA | 300 – 1500 Nm | 75 1/min |

| DS 80–130 / 2000 MDW or SA | 400 – 2000 Nm | 37 1/min |

| DS 80–130 / 2400 MDW or SA | 480 – 2400 Nm | 37 1/min |

Standard Options

- Motor Offset – side-mounted motor for a more compact design and shorter installation length

- Mounting flange

- Direct output variant (without spring deflection) with 1″ square drive (up to 1000 Nm) or 1.5″ square drive (up to 2400 Nm)

- Spring output with 50 mm spring deflection, available with 1″ square drive (up to 1000 Nm) or 1.5″ square drive (up to 2400 Nm)