Tightening Technique

Efficient, durable and repeatable

Tightening Technique

Manual and Automated Screwdriving Solutions

DSM provides high-performance electric screwdriving systems for industrial assembly – from ergonomic handheld nutrunners to stationary tightening solutions with precise built-in nutrunners for semi- and fully automated applications.

Our systems stand out through modular design, a wide variety of configurations, and maximum process reliability.

Whether used manually or integrated into a stationary setup: with various drive and output modules and a broad torque range, we offer tailored solutions for nearly any tightening task.

Benefit from proven technology that can be precisely adapted to your requirements.

Click the button to download the form directly. Complete the inquiry form, save it, and send it via email to DSM or upload the saved file through the contact form.

Tightening technology is a generic term encompassing tools, systems, machines and components used in the manufacturing of detachable screw connections.

What is a screw connection?

A screw connection consists of components that are held together thanks to the assembly preload force with the help of:

- Screws

- Nuts

- Blind rivet nuts

- Bolts

Tightening technology includes processes like screw feeding, screw positioning as well as the rotational and feed movements of the tool while tightening.

These functions make tightening technology tools widely applicable in the manual, semi-automatic and fully automatic assembly.

Further it can also be used in the final assembly stages in manufacturing and processing industries.

Another important aspect is the potential for non-destructive disassembly for post-processing, repairs or maintenance.

This is how it works

Screw connections are secured through the static friction of the thread and additional screw-locking elements.

The main focus of tightening technology is to determine and set the appropriate assembly preload force for the screw connection.

To achieve that goal the torque and angle of rotation need to be calculated correctly.

Drive

An electronically commutated motor (EC motor) serves as the drive.

It enables the calculation of torque and angle of rotation using the motor control parameters or torque and angle of rotation measurements.

As opposed to pneumatic tightening technology, electronically operated tightening technology is not dependent on the availability of compressed air.

Further advantages include flexibility, process reliability, torque accuracy, and the ability to provide seamless documentation.

Flexibility

Thanks to the EC motor and EC tightening technology, it is possible to freely adjust parameters such as speed, torque, angle of rotation, direction of rotation and screw-in depth.

This allows every screwing process to be modified at any time.

Also, an adaptation to new requirements is always possible.

Process Reliability

EC tightening systems can identify, evaluate and document the assembly process.

Torque results can be measured and evaluated through independent sensors.

This is especially important when assembling safety-critical components.

Torque Accuracy

Torque accuracy is determined by the critical machine capability index Cmk (capability machine katayori).

It indicates the ratio between tolerance and process spread of the machine.

The calculation also takes into account a deviation of the process mean value from the tolerance center.

Usually an ability examination is conducted, using a sample of 50 parts from a short production period.

Integrated Documentation

Unlike pneumatic nutrunners, electronically operated systems typically record torque and angle values automatically as a standard feature. This enables seamless process documentation and improves traceability for every fastening operation.

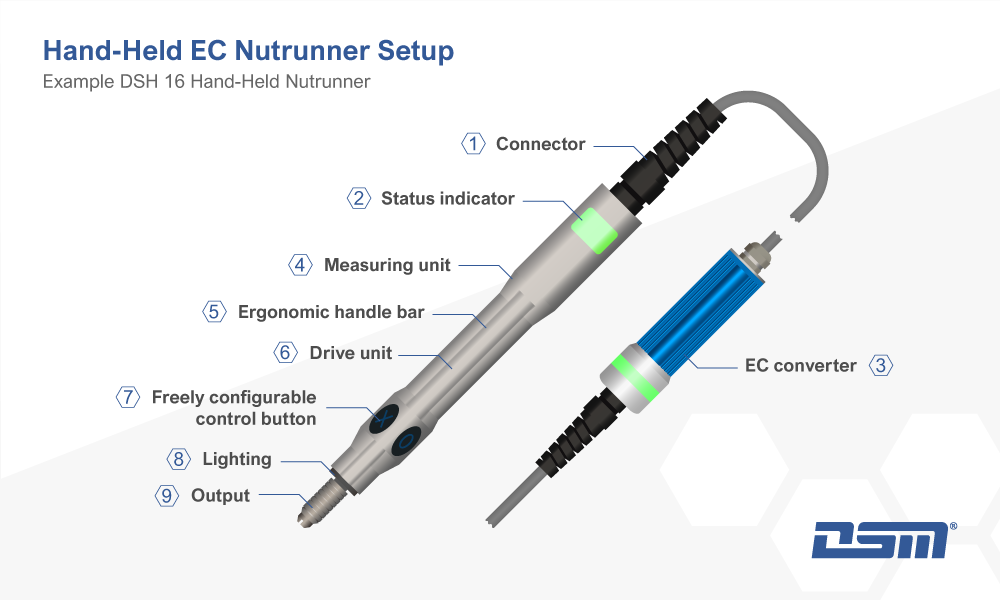

Our handheld EC nutrunners meet all requirements needed for a reliable assembly process.

Their compact and ergonomic design is perfect even for low torques.

Additionally, the highly accurate torque sensor accompanied by the DSM control system allows different tightening procedures to be carried out securely and according to quality requirements.

Thanks to the ergonomically shaped handle bar (5), the nutrunner lies comfortably in the hand, enabling barrier-free usage of the freely configurable control buttons (7).

The arrangement includes a program selector switch for switching between programs and a start button to initiate the selected program.

A status indicator (2) integrated in the handle displays the status of the tightening process: green indicates a proper fastening, yellow indicates an ongoing process and red indicates a faulty fastening.

The measuring unit (4) within the handle is for measuring and controlling the torque and angle of rotation.

At the end of the handle there is a connector (1) for the electronic selection and monitoring of the drive.

When using vacuum screw holders, the connector also includes the air or vacuum connection for an operating pressure of six bar.

Additionally, an integrated EC converter (3) ensures quick system integration and error-free setup.

Acting as decentralized intelligence it transfers characteristic data via plug-and-play.

Tightening operations can be performed even in dim light because of the additional lightning (8) located above the drive unit (6).

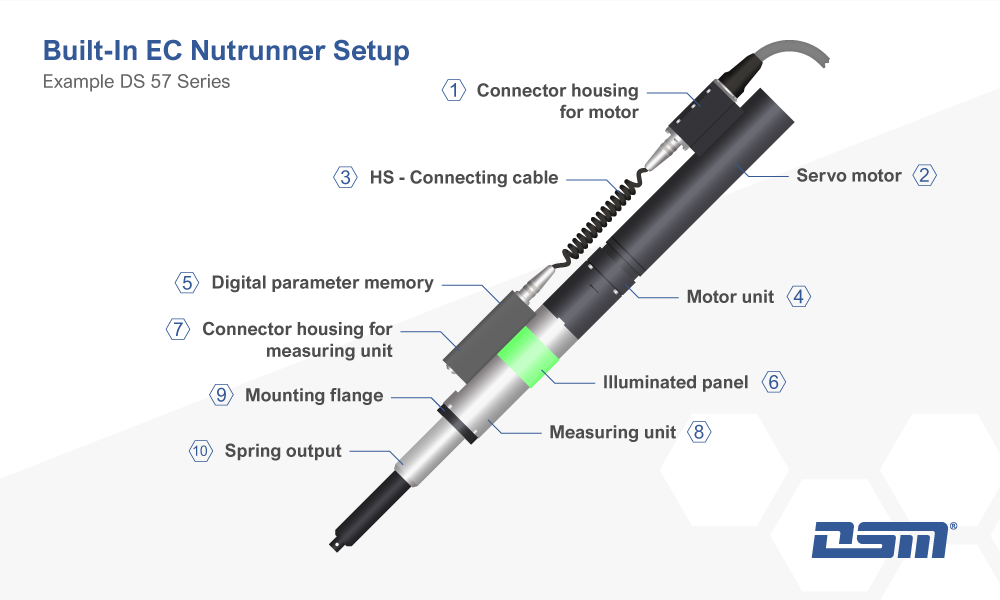

Our stationary screwdriving technology with built-in nutrunners from the DS series is the ideal solution for error-free and reliable production processes.

The main feature of this series is its compact design thus allowing perfect integration into existing or new production lines.

The built-in EC nutrunners are powered by an electronically controlled servo motor (2) and transfer digital data as well.

As with our handheld nutrunners, an integrated parameter memory ensures an error-free setup.

Additionally, the entire tightening process is controlled, monitored and supervised through the MultiPro 3G control system.

Since not every production process is the same, we offer our DS series with or without a torque sensor.

Thanks to the mounting flange (9), it is also possible to choose between various downforce units (10) such as:

- Drive offset

- Stubby drive

- Angle drive

- Self-start drive

- Offset drive

It is also possible to exchange them quickly.

An illuminated panel (6) is integrated in the housing to show the user the status of the process.

Green indicates a properly executed fastening, yellow shows that the process is ongoing and red signals there is a fault.