Precision technology

What We Offer

DSM is your specialist for precise, reliable, and cost-effective solutions for first-class assembly and testing processes.

Below, we provide a concise introduction to our scope of services – from intelligent control systems and modern tightening and press-in technologies to tailor-made custom solutions in hardware and software.

The right system for every assembly and testing process.

DSM control systems and software solutions are ideal for tightening and press-in tasks – with a unified operating concept.

The modular systems combine control electronics and servo control in a single housing.

With the MultiPro 3G, DSM offers its most advanced control solution – developed to meet current and future requirements in tightening and press-in technology.

The platform combines intuitive usability with a flexible hardware and software framework.

Its wide range of functions can be adapted to individual needs. DSM develops process-specific features with customer focus and technical expertise – new functions can be easily integrated as add-ons.

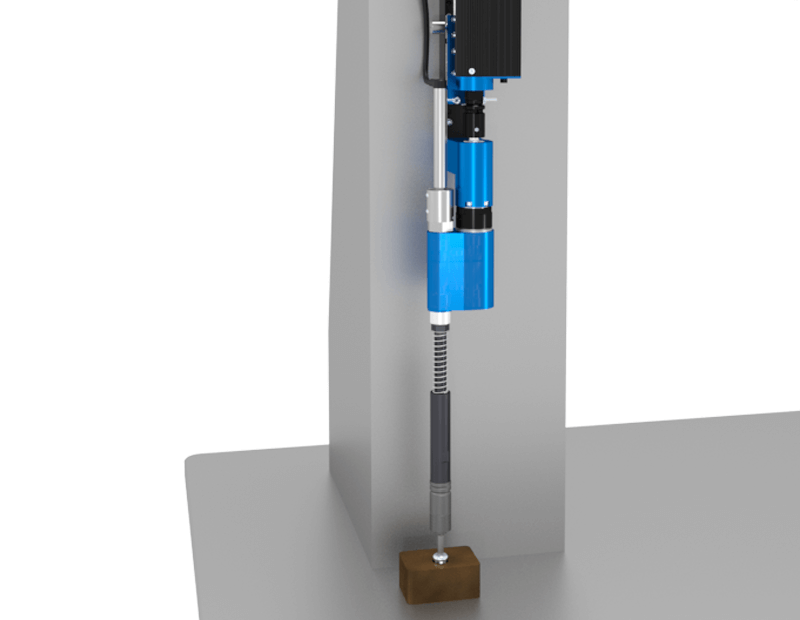

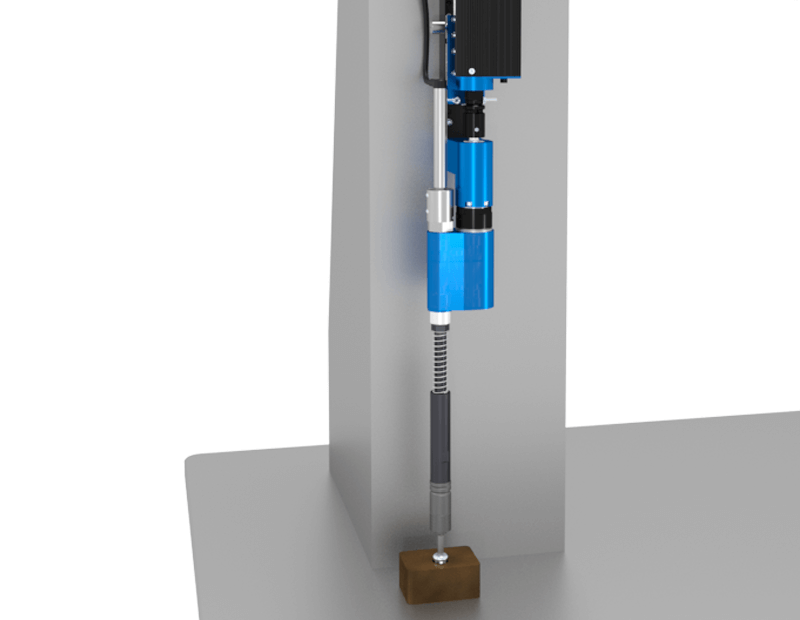

The right nutrunner for every task – in the appropriate size, with the required torque, and the demanded precision.

The DS series of built-in nutrunners and the DSH series of handheld nutrunners offer a wide range of drive and output options – and can be precisely configured for your specific application.

Thanks to in-house manufacturing, individual customizations are also easily achievable.

The nutrunners transmit data digitally – with only one connection cable (up to 60 Nm) and integrated decentralized intelligence. Additionally, the nutrunner features an LED indicator to display the tightening status.

For the highest measurement accuracy, the MDW version is equipped with a torque sensor calibrated according to DAkkS standards.

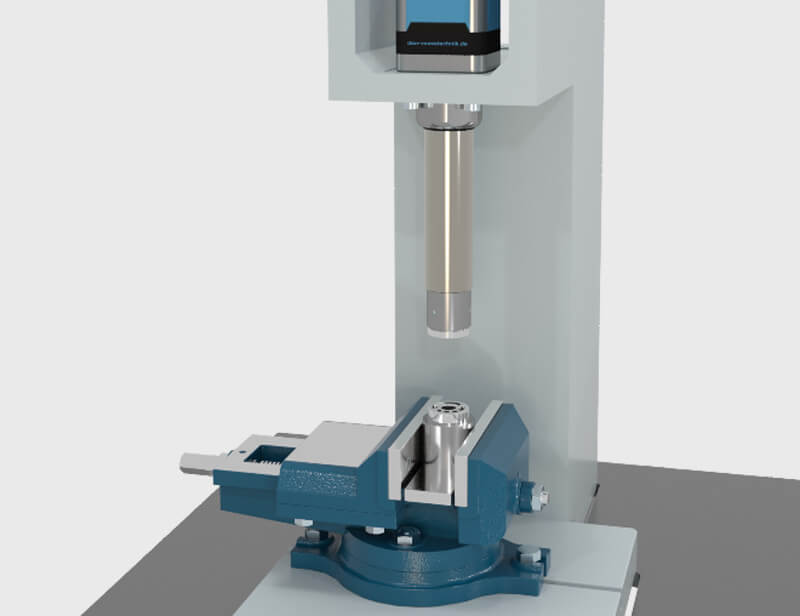

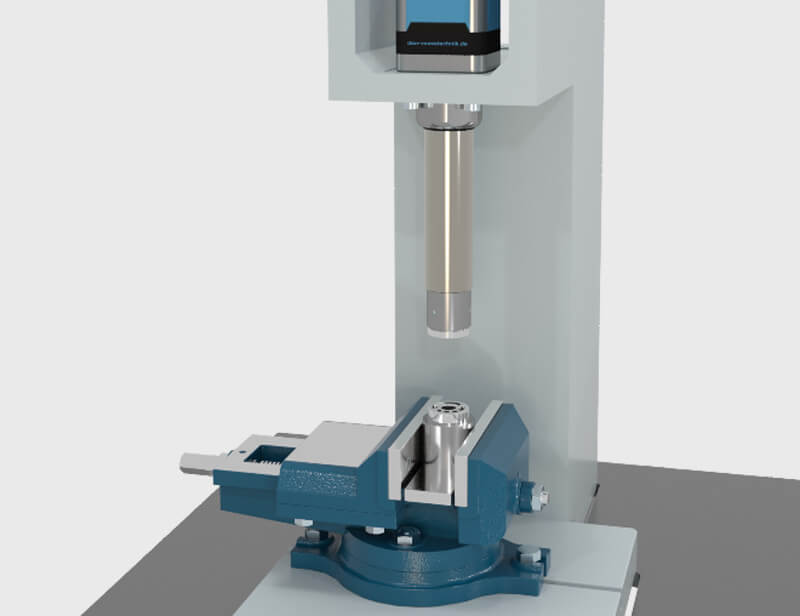

The right press-in unit for press, joining and forming tasks.

DSM offers servo-electric press-in units from the QMP, SMP and XMP series, specifically tailored to your applications.

Available in the appropriate size, with the required force, the demanded precision, and the suitable joining stroke.

In the field of servo-electric press-in units, DSM covers a force range from 50 N up to 120,000 N.

Thanks to robust design and high durability, our press-in units are ideal for continuous industrial operation.

Depending on your needs, we equip the press-in units with increased stroke, backstop, or electromechanical brake. Custom versions are always possible thanks to in-house manufacturing.