Tightening technique

Handheld Nutrunners – DSH Series

DSM offers a wide range of powerful handheld and pistol grip nutrunners for manual screwdriving processes in industrial assembly.

Our electronically controlled screwdriving tools combine precise DSM tightening technique, excellent ergonomics, and maximum process reliability – making them ideal for safety- and quality-critical applications in demanding assembly environments.

Those seeking reliable and efficient assembly processes choose DSM’s digital handheld and pistol grip nutrunners. The DSH series impresses with its broad variety of configurations and support for the diverse tightening methods of the MultiPro 3G – enabling error-free fastening, reproducible results, and ensuring the highest product quality throughout the entire production process.

Manual Screwdriving Technology for Industrial Use

- Digital handheld nutrunners for manual applications

- Torque ranges from 0.05 Nm to 60 Nm

- Error-free setup via integrated parameter memory

- Maintenance-free, brushless servo motor with clockwise/counterclockwise rotation

- Durable housing made of stainless steel and aluminum

- Wear-free operating elements for long service life

- Various output options for maximum flexibility

Accessories for DSH Handheld Nutrunners

Expand your application possibilities with field-proven accessories: crowfoot gear units, suspension elements, balancers, tool change boxes, handling systems, and customized technical solutions on request.

▶ What’s the Right Torque for Your Application?

Our “Bolt Tightening Torque Chart” provides tips and typical reference values for standard metric threads – a practical guide for selecting the right nutrunner.

Select a Series

for More Information:

0.05 – 0.5 Nm (2 versions)

0.05 – 4 Nm (4 versions)

0.1 – 5 Nm (4 versions)

0.5 – 15 Nm (4 versions)

1 – 20 Nm (4 versions)

1 – 15 Nm (3 versions)

0.5 – 35 Nm (5 versions)

4 – 60 Nm (4 versions)

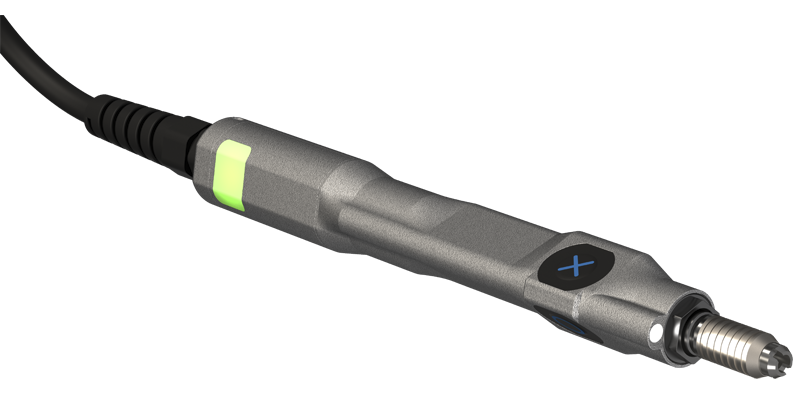

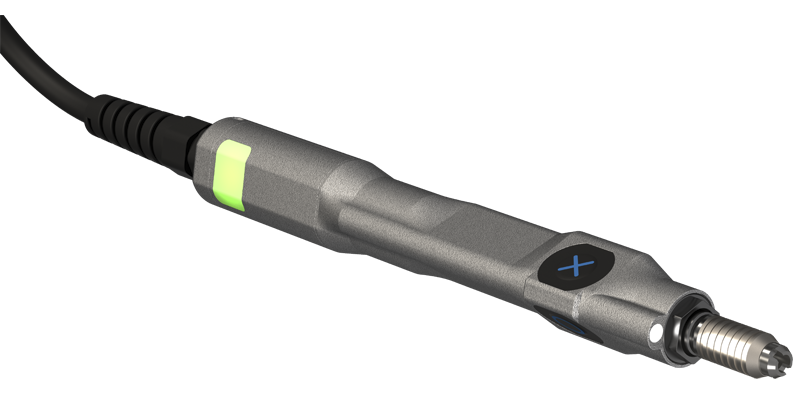

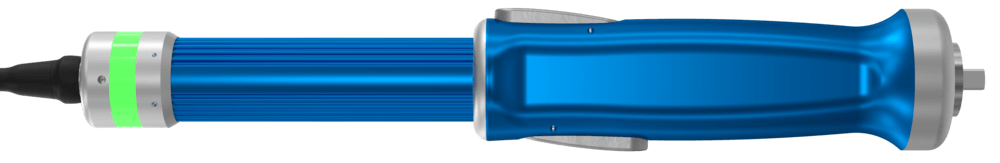

The miniaturization of many products presents a particular challenge for manufacturing – especially in terms of process-reliable assembly.

To meet this need, we developed the DSH 16 nutrunner for extremely low torque values, suitable for both handheld use and integration into automated systems.

The DSH 16 series is available in torque versions of 0.25 Nm and 0.5 Nm.

Standard Equipment:

- Status indication vialight field

- External EC converter with plug-and-play parameter transmission

- Motor-gear unit

- Control button “O” to start the program sequence

- Control button “X” to switch to the alternative program (PG 128)

- Ergonomic handle

- Headlight for illumination of the application

- Suspension clip

- Fixed output with quick-change chuck for 4 mm halfmoon and HIOS bits

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via motor sensors

- Angle resolution: 0.89°

For more information on calibration and traceability, please refer to the “Calibration” page.

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DSH 16 / 0025 MDW | 0.05 – 0.25 Nm | 450 1/min |

| DSH 16 / 005 MDW | 0.1 – 0.5 Nm | 450 1/min |

Standard Options

- Mounting adapter with external thread M15×1

- Vacuum screw holder with 2 mm spring deflection

- Vacuum connection directly on the nutrunner

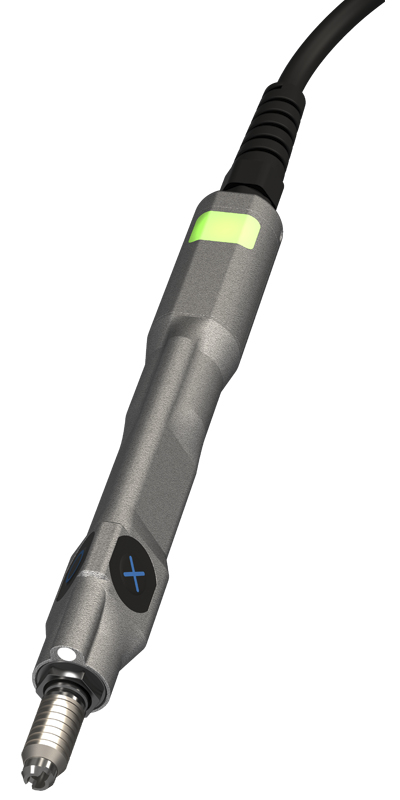

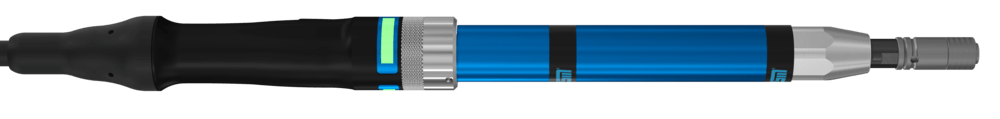

Handheld nutrunner with electronically controlled servo motor and digital data transmission.

The DSH 26 series is available in 0.5 Nm, 1 Nm, 2 Nm, and 4 Nm versions – either as an MDW type (with digital torque sensor) or as a current-controlled SA type.

Standard Equipment:

- Status indication via light field

- Plug-and-play parameter transmission

- Motor and gearbox integrated in an aluminum housing

- Control button to switch to the alternate program (PG 128)

- Button to start the program sequence

- Ergonomic handle

- Headlights for illumination of the application

- Suspension clip

- Fixed output without attachment – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via motor sensors

- Angle resolution: 3.7° (DSH26/005, 26/01); 2.6° (DSH26/02);

1.0° (DSH26/04)

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 4.3° (DSH26/005, 26/01); 2.1° (DSH26/02);

1.0° (DSH26/04) - Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed (MDW) | Speed (SA) |

|---|---|---|---|

| DSH 26 / 005 | 0.05 – 0.5 Nm | 1450 1/min | 1700 1/min |

| DSH 26 / 01 | 0.2 – 1 Nm | 1450 1/min | 1700 1/min |

| DSH 26 / 02 | 0.4 – 2 Nm | 1020 1/min | 820 1/min |

| DSH 26 / 04 | 0.8 – 4 Nm | 400 1/min | 400 1/min |

Standard Options

- Spring output with 20 mm or 50 mm spring deflection

- Self-start output with 5 mm spring deflection – tightening process starts automatically when compressed

- Angle head with DIN 3126 D6.3 quick-change chuck

- Vacuum screw holder

- Output unit with galvanic isolation

- Output features (1/4″ hex/square, quick-change chuck B3/B5.5/D6.3) – compatible with fixed, spring output, or self-start output

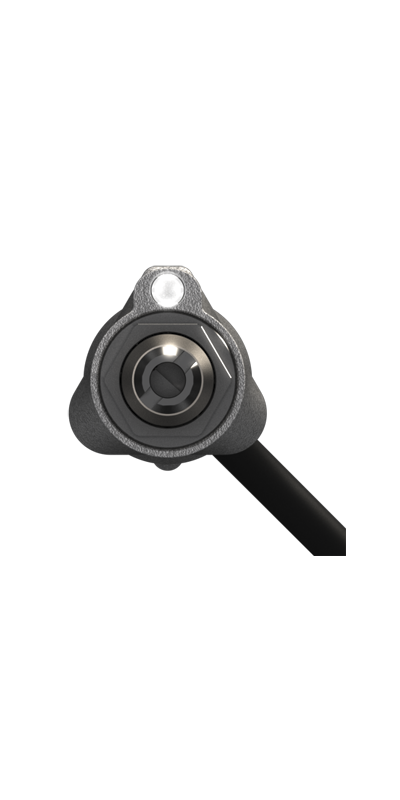

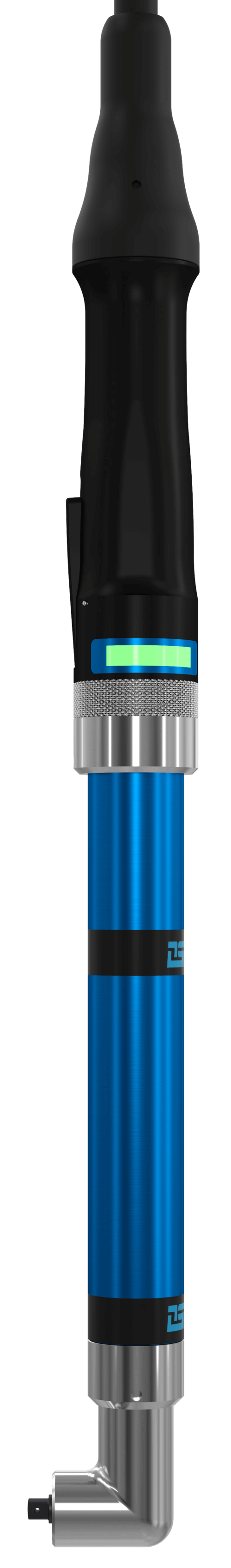

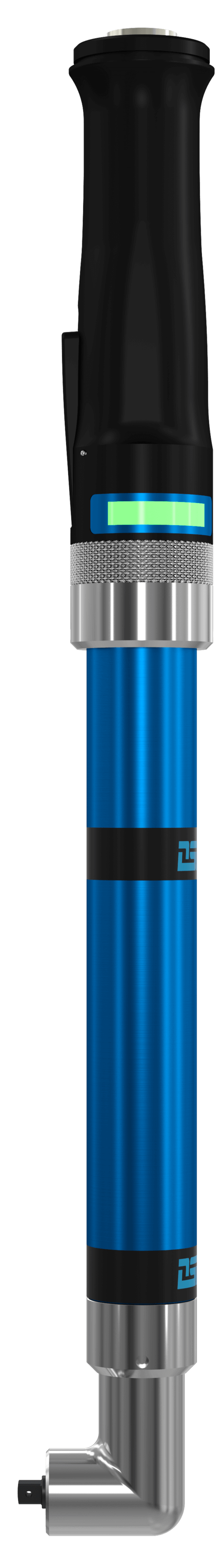

DSH 28 – precise and versatile: usable as a handheld nutrunner, as a guided tool in handling systems, or as a built-in nutrunner in automated processes.

The DSH 28 series is available in 0.6 Nm, 1.2 Nm, 2.2 Nm, and 5 Nm versions – either as an MDW type (with digital torque sensor) or as a current-controlled SA type.

Standard Equipment:

- Tightening status via integrated light field

- PG S and PG A LEDs for program status (active or alternate program)

- Plug-and-play parameter transmission

- High-performance motor-gear combination

- Button to start the program sequence

- Two freely configurable control buttons:

– Program switch (to alternate program PG 128)

– Control functions, e.g. defined output on/off - Ergonomic handle with honeycomb texture for optimal grip

- LED screw point illumination with three modes: On, Off, and Auto

- Fixed output with D6.3–24 mm quick-change chuck

- Additional output variants available – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via motor sensors

- Angle resolution: 3.5° (DSH28/006, 28/012); 2.5° (DSH28/022);

1,0° (DSH28/05)

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 4.2° (DSH28/006, 28/012); 2.4° (DSH28/022);

1.0° (DSH28/05) - Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed (MDW) | Speed (SA) |

|---|---|---|---|

| DSH 28 / 006 | 0.1 – 0.6 Nm | 1330 1/min | 1610 1/min |

| DSH 28 / 012 | 0.2 – 1.2 Nm | 1330 1/min | 1610 1/min |

| DSH 28 / 022 | 0.4 – 2.2 Nm | 965 1/min | 910 1/min |

| DSH 28 / 05 | 0.9 – 5 Nm | 370 1/min | 370 1/min |

Standard Options

- Suspension device for mounting the nutrunner, e.g. on a balancer

- Spring output with 20 mm, 50 mm or 70 mm spring deflection

- Self-start output – tightening process starts automatically when compressed

- Length measurement sensor for thread entry detection and depth control

- Vacuum screw holder with direct vacuum connection at the nutrunner

- Angle head with D6.3–13 mm quick-change chuck

- Output offset (angled output) with 20 mm spring deflection and D6.3–24 mm quick-change chuck – reduces hole pattern spacing and improves access in confined areas

- Output unit with galvanic isolation

- Output features (1/4″ square, D6.3 quick-change chuck) – can be combined with fixed, spring output, or self-start output

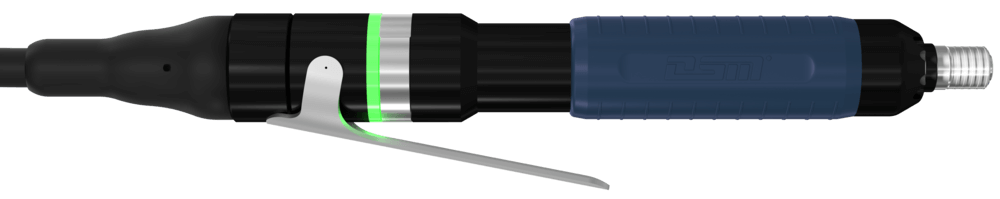

Pistol grip nutrunner with electronically controlled servo motor and digital data transmission.

The DS-34‑P series is available in 2.5 Nm, 5 Nm, 10 Nm, and 15 Nm versions – either as an MDW type (with digital torque sensor) or as a current-controlled SA type.

Standard Equipment:

- Status indication via illuminated field

- Plug-and-play parameter transmission

- Motor and gearbox integrated in an aluminum housing

- Button to start the program sequence

- Rotary dial for speed limitation

- Function switch to toggle to the alternate program (PG128)

- Pistol grip handle

- Suspension bracket

- Fixed, without output – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via digital absolute encoder

- Angle resolution: 0.1°

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 3.3° (DS34/05); 1.7° (DS34/10, 34/15)

- Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DS 34 / 025 MDW‑P | 0.5 – 2.5 Nm | 880 1/min |

| DS 34 / 05 MDW‑P or SA‑P | 1 – 5 Nm | 880 1/min |

| DS 34 / 10 MDW‑P or SA‑P | 2 – 10 Nm | 1540 1/min |

| DS 34 / 15 MDW‑P or SA‑P | 3 – 15 Nm | 1540 1/min |

Standard Options

- Spring output with 30 mm or 50 mm spring deflection

- Output unit with galvanic isolation

- Output features (1/4″ / 3/8″ square, D6.3–24 mm quick-change chuck) – compatible with direct or spring output

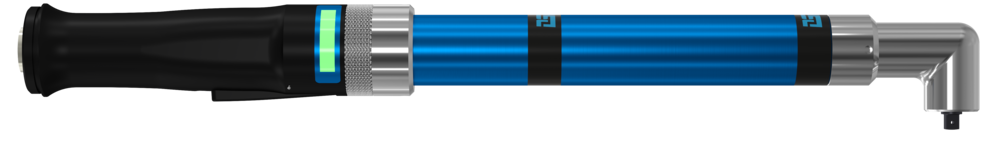

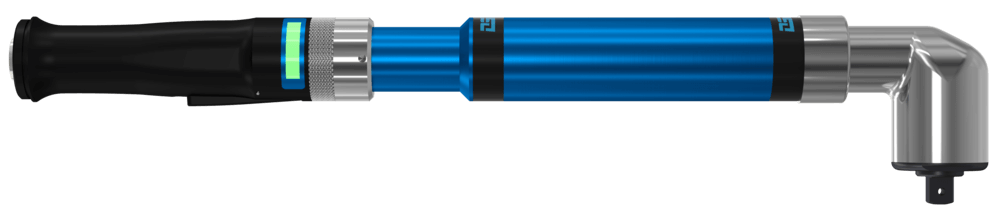

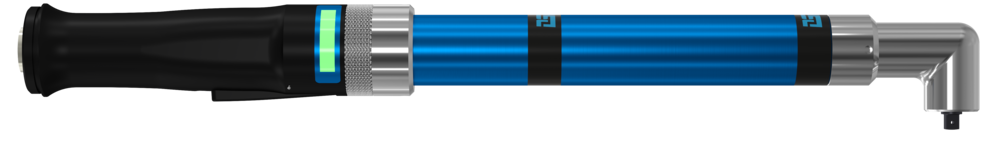

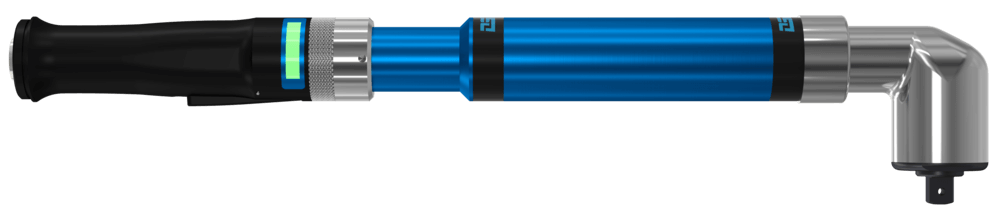

Handheld nutrunner with electronically controlled servo motor and digital data transmission.

The DSH 34 series is available with straight output in 5 Nm and 10 Nm versions, and with angle head in 5 Nm, 10 Nm, and 20 Nm versions – either as an MDW type (with digital torque sensor) or as a current-controlled SA type.

Standard Equipment:

- Illuminated field for tightening status indication

- Plug-and-play parameter transmission

- Motor and gearbox integrated in a robust housing

- Button to start the program sequence

- Selector ring to switch to the alternate program (PG 128)

- Ergonomic handle

- Suspension mount / Suspension clip

- Angle head with 3/8″ square drive

- Straight output, fixed – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via motor sensors

- Angle resolution: 1.7° (straight output); 1.2° (angle head)

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 1.7° (straight output); 1.2° (angle head)

- Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed (Straight) | Speed (Angle Head) |

|---|---|---|---|

| DSH 34 / 05 MDW or SA | 1 – 5 Nm | 1540 1/min | 1070 1/min |

| DSH 34 / 10 MDW or SA | 2 – 10 Nm | 1540 1/min | 1070 1/min |

| DSH 34 / 20 MDW or SA* | 4 – 20 Nm | - | 1070 1/min |

*Version only available with angle drive

Standard Options

- Spring output with 30 mm or 50 mm spring deflection

- Output unit with galvanic isolation

- Output features (1/4″ / 3/8″ square drive, D6.3–24 mm quick-change chuck) – compatible with direct or spring output

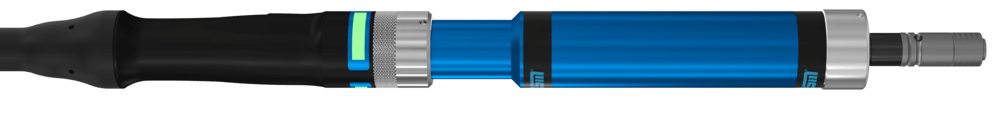

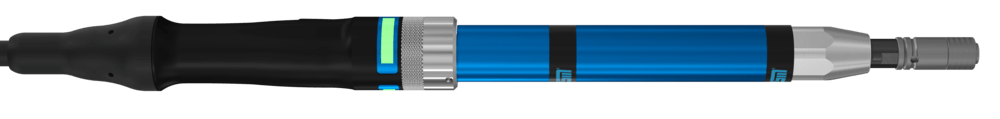

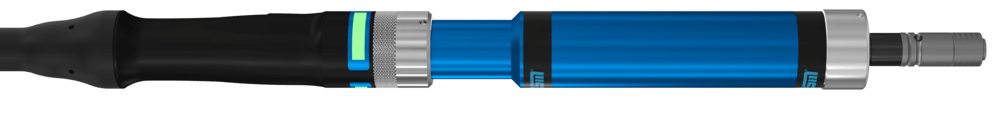

Handheld nutrunner with electronically controlled servo motor and digital data transmission.

The DSH 38 series is available in torque versions of 5 Nm, 10 Nm, and 15 Nm.

Standard Equipment:

- Illuminated field for tightening status indication

- Plug-and-play parameter transmission

- Motor and gearbox integrated in a robust housing

- Button to start the program sequence

- Selector ring to switch to the alternate program (PG 128)

- Ergonomic handle

- Headlights for illumination of the application

- Straight output with D6.3–24 mm quick-change chuck

- Additional output variants available – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via motor sensors

- Angle resolution: 0.01°

For more information on calibration and traceability, please refer to the “Calibration” page.

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DSH 38 / 05 MDW | 1 – 5 Nm | 1540 1/min |

| DSH 38 / 10 MDW | 2 – 10 Nm | 1540 1/min |

| DSH 38 / 15 MDW | 3 – 15 Nm | 1540 1/min |

Standard Options

- Self-start output with 5 mm spring deflection and D6.3–24 mm quick-change chuck

- Output unit with galvanic isolation (GT)

- Output features (1/4″ / 3/8″ square drive, D6.3–24 mm quick-change chuck) – compatible with GT output unit

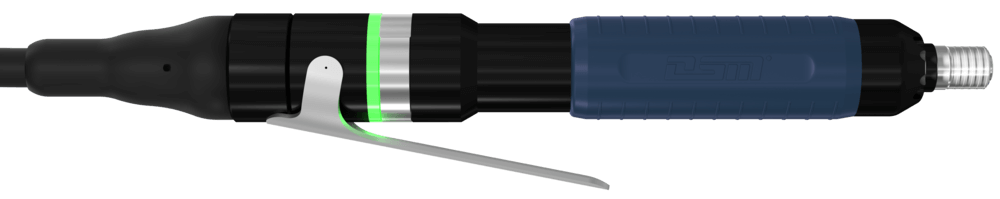

Pistol grip nutrunner with electronically controlled servo motor and digital data transmission.

The DS-44‑P series is available in 2.5 Nm, 5 Nm, 10 Nm, 20 Nm, and 35 Nm versions – either as an MDW type (with digital torque sensor) or as a current-controlled SA type.

Standard Equipment:

- Status indication via illuminated field

- Motor and gearbox integrated in an aluminum housing

- Button to start the program sequence

- Rotary dial for speed limitation

- Function switch to toggle to the alternate program (PG128)

- Pistol grip handle

- Suspension bracket

- Fixed, without output – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via digital absolute encoder

- Angle resolution: 0.1°

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 3,3° (DS44/05); 2,3° (DS44/10); 1,4° (DS44/20);

1,0° (DS44/35) - Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Torque Range | Speed |

|---|---|---|

| DS 44 / 025 MDW‑P | 0.5 – 2.5 Nm | 1300 1/min |

| DS 44 / 05 MDW‑P or SA‑P | 1 – 5 Nm | 1300 1/min |

| DS 44 / 10 MDW‑P or SA‑P | 2 – 10 Nm | 900 1/min |

| DS 44 / 20 MDW‑P or SA‑P | 4 – 20 Nm | 530 1/min |

| DS 44 / 35 MDW‑P or SA‑P | 7 – 35 Nm | 480 1/min |

Standard Options

- Spring output with 30 mm or 50 mm spring deflection

- Output unit with galvanic isolation

- Output features (1/4″ / 3/8″ square, D6.3–24 mm quick-change chuck) – compatible with direct or spring output

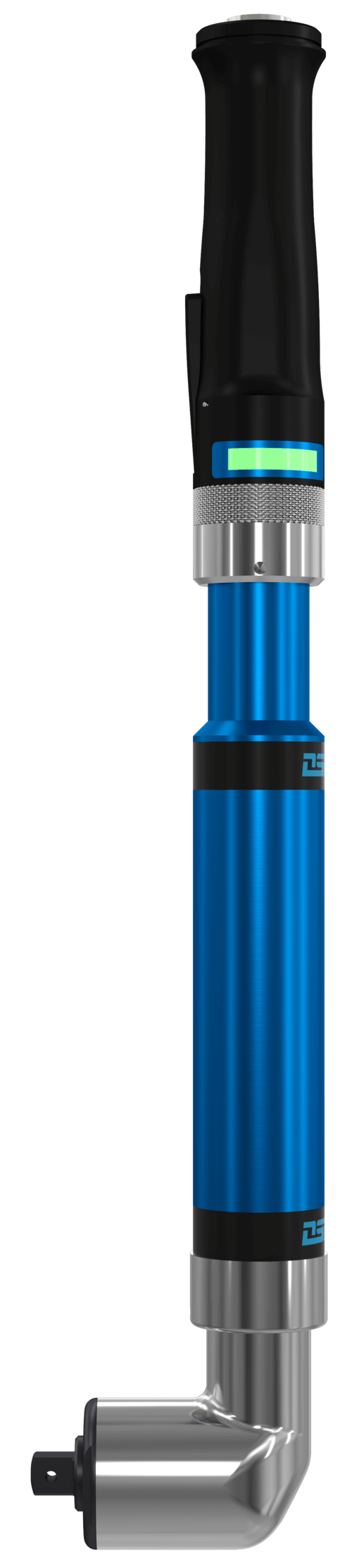

Handheld nutrunner with electronically controlled servo motor and digital data transmission.

The DSH 44 series is available with straight output in 20 Nm and 30 Nm versions, and with angle head in 40 Nm and 60 Nm versions – either as an MDW type (with digital torque sensor) or as a current-controlled SA type.

Standard Equipment:

- Illuminated field for tightening status indication

- Plug-and-play parameter transmission

- Motor and gearbox integrated in a robust housing

- Button to start the program sequence

- Selector ring to switch to the alternate program (PG 128)

- Ergonomic handle

- Suspension mount / Suspension clip

- Angle head with 1/2″ square drive

- Straight output, fixed – see standard options

MDW Control Type

- Directly integrated torque measurement via DAkkS-calibrated digital sensor

- Torque accuracy: 0.5% of final value

- Tolerance according to ISO 5393: better than 5%

- Angle measurement via motor sensors

- Angle resolution: 1.0°

For more information on calibration and traceability, please refer to the “Calibration” page.

SA Control Type

- Indirect torque measurement via current-controlled shut-off

- Torque accuracy depends on tool calibration – adjustment via reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Angle detection via motor sensors

- Angle resolution: 1.0°

- Cost-effective solution for simple tightening tasks

Torque Ranges & Speeds

| Version | Output | Torque Range | Speed |

|---|---|---|---|

| DSH 44 / 20 MDW or SA | Straight Output | 4 – 20 Nm | 680 1/min |

| DSH 44 / 30 MDW or SA | Straight Output | 6 – 30 Nm | 680 1/min |

| DSH 44 / 40 MDW or SA | Angle Head | 8 – 40 Nm | 350 1/min |

| DSH 44 / 60 MDW or SA | Angle Head | 12 – 60 Nm | 350 1/min |

Standard Options

- Spring output with 30 mm or 50 mm spring deflection

- Output unit with galvanic isolation

- Output features (1/4″ / 3/8″ square drive, D6.3–24 mm quick-change chuck) – compatible with direct or spring output