Precision technology for assembly processes

On board with our quality

About Us

Welcome to DSM

Quality from DSM is in a large share of vehicles worldwide – many of which are assembled using our tightening and press-in technology.

Our precise, custom-engineered tightening, press-in and measuring technique ensures outstanding and reliable assembly processes – in the automotive industry as well as in aerospace, electrical engineering, and mechanical engineering.

Today, DSM products are used in over 1,000 companies across Europe, South America, and Asia – and are recognized worldwide for their quality, precision, and efficiency.

Everything at a glance

Scope of Service

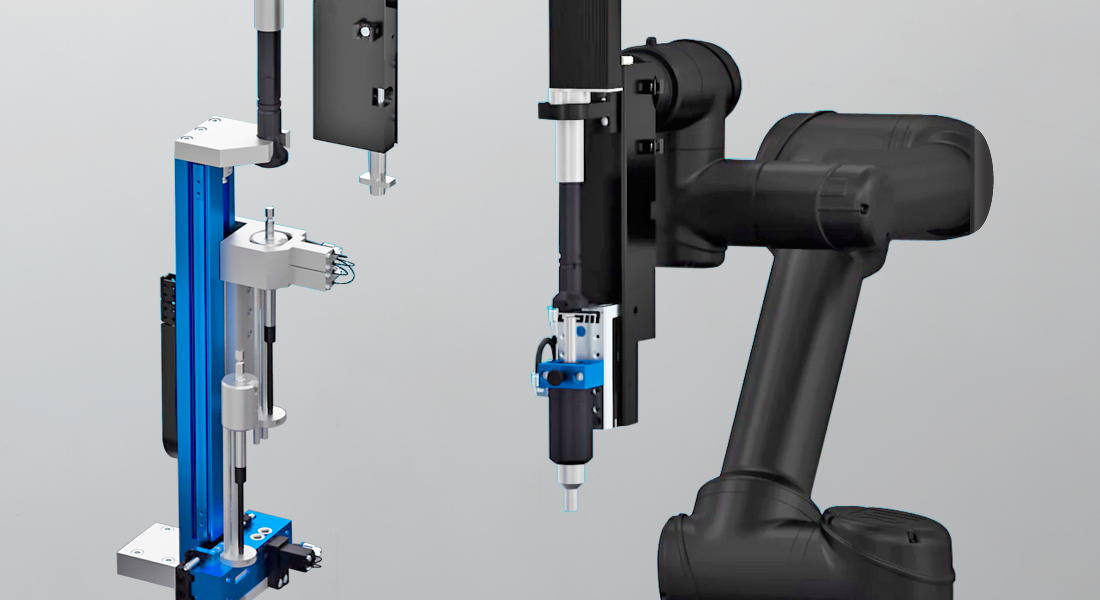

Tightening Technology for Assembly & Testing

Handheld nutrunners and built-in nutrunners for manual, automated, and fully automated assembly and testing applications – precise, reliable, and process-safe.

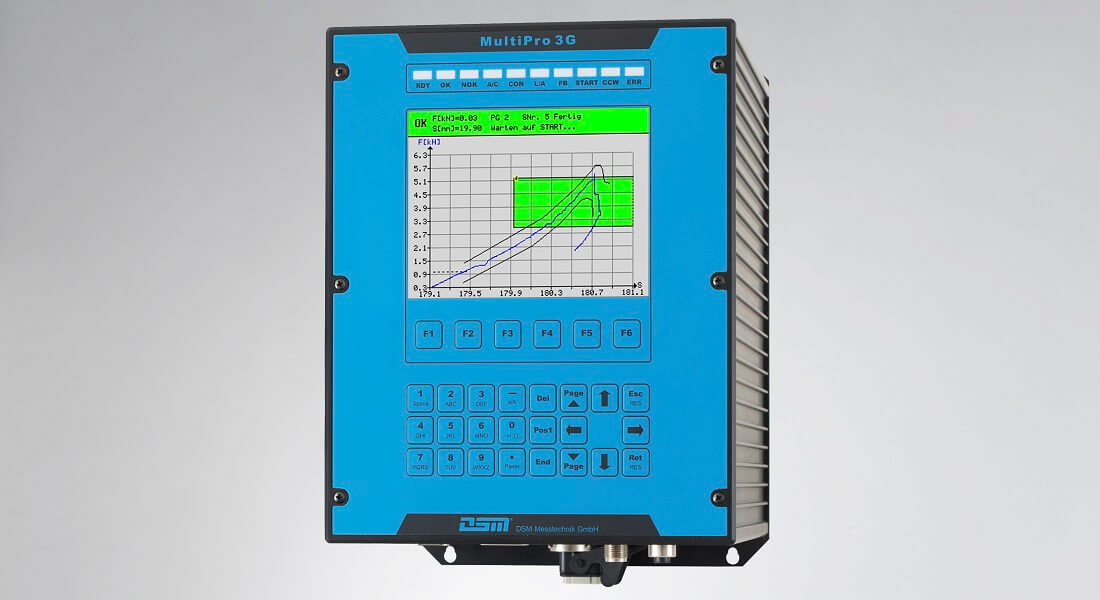

Tightening and Press-In Control System

One control system for everything. The MultiPro 3G is the central platform for tightening and press-in processes – modular, smart, and equipped with interfaces for modern manufacturing networks.

High-Precision Measurement Technology

The QS Box is a digital measuring system for quality assurance of process operations. When used with the MultiPro 3G, external sensor data can be directly integrated into the evaluation process.

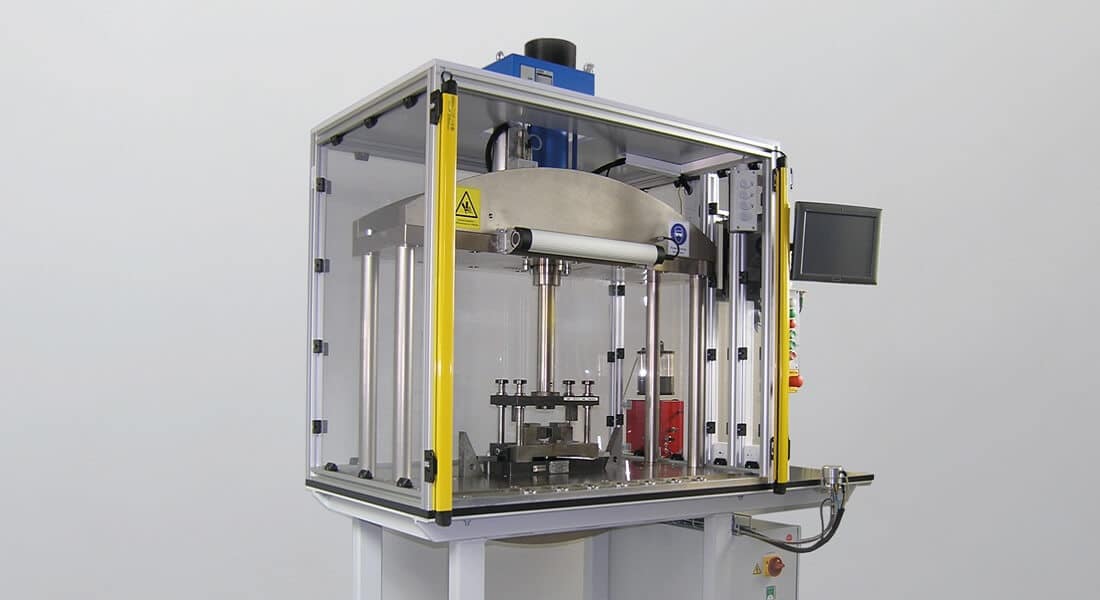

Working Better with DSM Handling Systems

Low-fatigue work in assembly with the handling stands of the HST series and the handling swivel arms of the HSA series – also with integrated position monitoring.

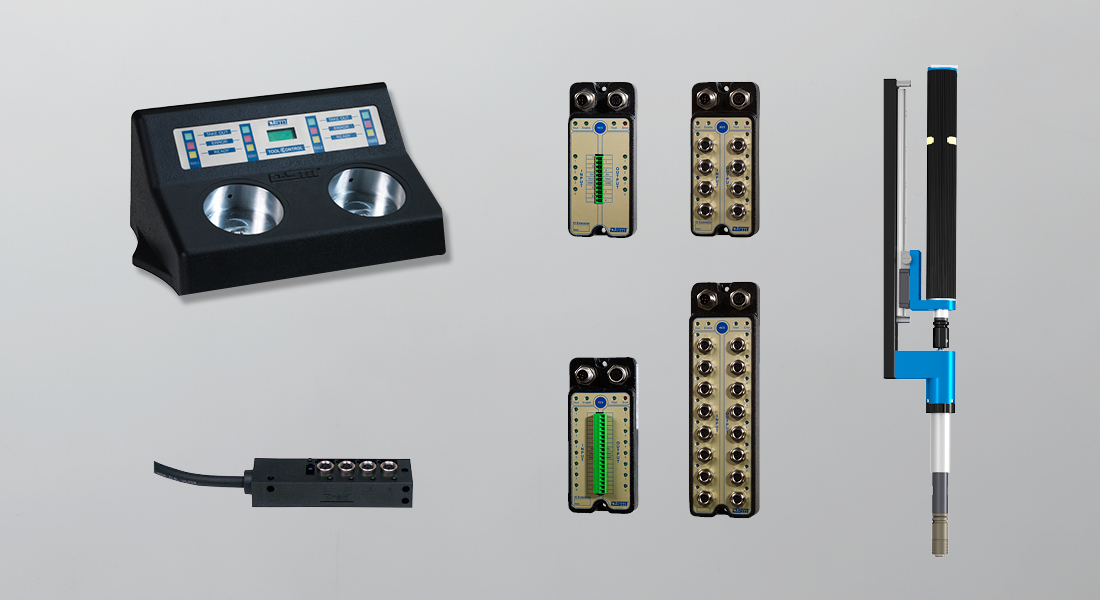

Useful Accessories

IO Extension for more inputs and outputs, comfortable connection with the I/O Expander, the tool change box ToolControl or the Linear module for your QA.

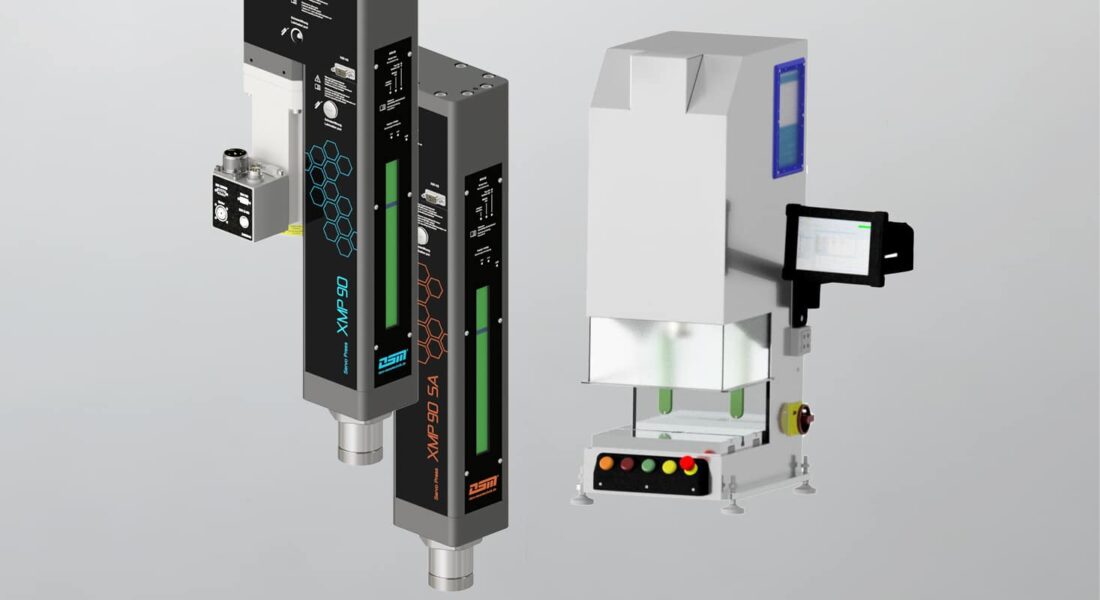

Workstations as a Complete Solution

Individual, technically advanced single workstations. Compact all-in-one systems – the XMP BenchPressUnit. For special requirements: customized special solutions.