EC nutrunners are an integral part of many assembly processes in numerous companies and are utilized in various industries.

EC Nutrunners — Definition and Types

An EC nutrunner is an electronically controlled tool designed for the precise fastening and removal of screws.

Generally, there are two types:

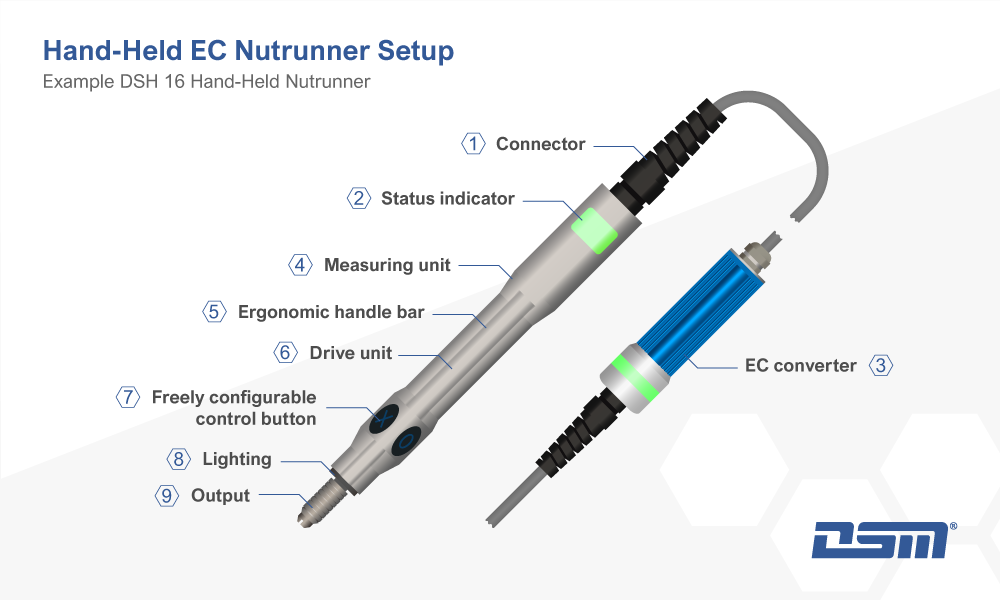

- Hand-held nutrunners for mobile use

- Built-in nutrunners for stationary applications

Meaning

EC nutrunner is an abbreviation for electronically commutated nutrunner.

The electronic control ensures accurate torque regulation during tightening, resulting in increased precision.

This not only helps to maintain consistent quality in each individual assembly step, but also prevents material damage.

Therefore, EC nutrunners are particularly suited for precision work and are widely used in industrial mass production.

Applications include:

- Automotive industry

- Manufacturing of electronics

- Mechanical engineering

- Medical technology

Although it seems obvious to compare EC nutrunners with cordless screwdrivers, they differ greatly in terms of performance.

Motors in standard products do not achieve the required precision at higher torques to correctly fasten specific screws.

Compact cordless screwdrivers sold for household use have torques significantly below 10 Nm.

On the other hand, hand-held nutrunners for professional assembly are available with torques ranging from 0.05 to 60 Nm — built-in nutrunners even with up to 2400 Nm.

EC Nutrunners: Safe and Efficient Manufacturing

In manufacturing EC nutrunners are of considerable significance as their combined use with other tools greatly enhances workflow and efficiency.

The electronic regulation of the motor helps to avoid undesirable side effects that can occur with manual or pneumatic tightening.

Advantage

Mainly EC nutrunners prevent overtightening or undertightening of screws, thus protecting components from substantial damage.

Screws can be fastened more quickly and each time with consistently applied pressure.

Insufficient clamping force is among the many results of using the incorrect torque and can lead to failure of a screw fitting.

Such defects can occur not only during assembly, but also during disassembly which is sometimes needed for maintenance purposes.

As a consequence, the function of an entire system can be impaired because of one screw.

In addition, many industries require the use of special screws that, due to their shape, have specific installation requirements.

Achieving the correct torque can be especially challenging when it comes to small screw connections.

Therefore, it is crucial to choose an EC nutrunner tailored to the intended task.

Overview: 3 Types of EC Nutrunners

The key factors to consider when choosing the right EC nutrunner include:

- Correct torque

- Size and shape of the screws to be fastened

- Working environment

In high-volume manufacturing, ergonomically shaped nutrunners significantly relieve the workforce.

There are 3 common forms of EC nutrunners:

| Form | Function | DSM models |

|---|---|---|

| Straight | Universally applicable for a secure assembly process. | DSH 16 DSH 26 DSH 38 DS 26 DS 34 DS 44 DS 57 DS 80 DS 80–130 |

| Pistol | Ideal for tasks that need to be performed with a lot of strength over extended periods of time. | DS 34‑P DS 44‑P |

| Angled | Ensure comfortable use, even in narrow workspaces. | DSH 34 DSH 44 |

Consistent documentation

EC nutrunners can not only record, but also evaluate and document the assembly process.

Compared to pneumatic technology they offer higher process reliability.