Tightening technique

Hand-held nutrunners DSH series

DSM offers a variety of high-performance tightening tools for virtually every field of application.

Digital hand-held tightening technique, reliable function and excellent quality, first-class ergonomics as well as an enormous range of versions speak for the handheld and pistol nutrunners from DSM.

Those on the lookout for perfect assembly processes choose DSM tightening technique.

Because with the DSH nutrunners – thanks to the variability of our tightening processes – you have a powerful system for error-free tightening in safety- and quality-critical assembly.

Reliable hand-held tightening technique with the highest quality.

- Digital hand-held tightening technique

- Nutrunners from 0.05 Nm to 60 Nm

- Error-free setup through integrated parameter memory

- Maintenance-free brushless servo motor, clockwise / anti-clockwise

- Robust housing made of stainless steel and aluminium

- Wear-free operating elements

- Diverse output versions

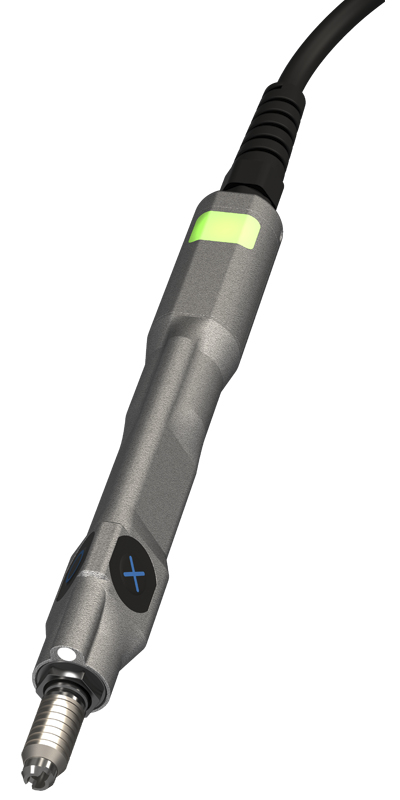

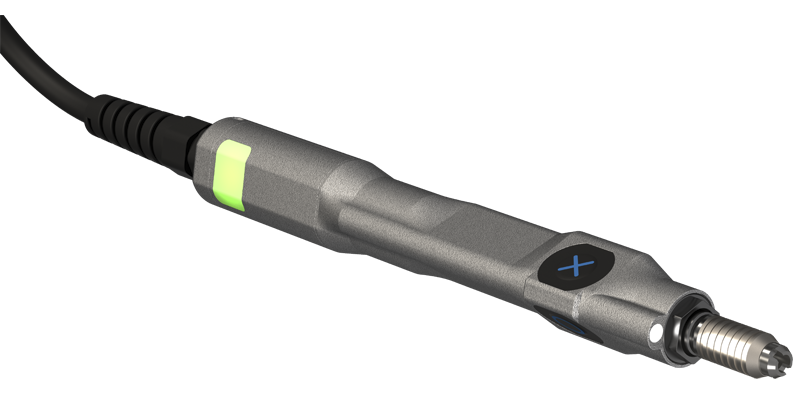

DSH 16 series

The miniaturisation of many products is a particular challenge in manufacturing – especially in the process-safe assembly. We therefore have developed the DSH 16 nutrunner for very low torques. The DSH 16 may be used for hand-guided operation as well as for automated processes. Available in torque versions of 0.25 Nm and 0,5 Nm.

- Status indicator via light field

- Motor-gear combination

- Freely configurable operating buttons

- Ergonomic handle

- Headlight for illumination of the application

- Vacuum connection for option “vacuum screw holder”

- Suspension clip

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 0.89°

- Speed max 450 rpm

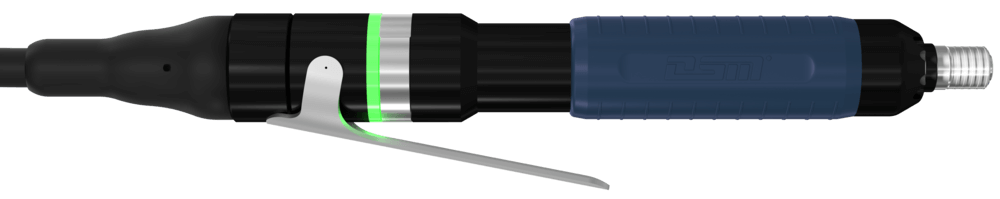

DSH 26 series

Hand-held nutrunner with electronically controlled servo motor and digital data transmission. Available in torque versions 0.5 Nm, 1 Nm, 2 Nm and 4 Nm.

- Status indicator over light field

- Motor and gear are integrated in an aluminium housing

- Ergonomic aluminium handle

- Start button and programmable function switch

- Headlights for illumination of the application

- Suspension clip

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 3.7° (DSH26/005, 26/01); 2,6° (DSH26/02); 1,0° (DSH26/04)

SA design

- Torque measurement indirectly via current cut-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 4.3° (DSH26/005, 26/01); 2.1° (DSH26/02); 1.0° (DSH26/04)

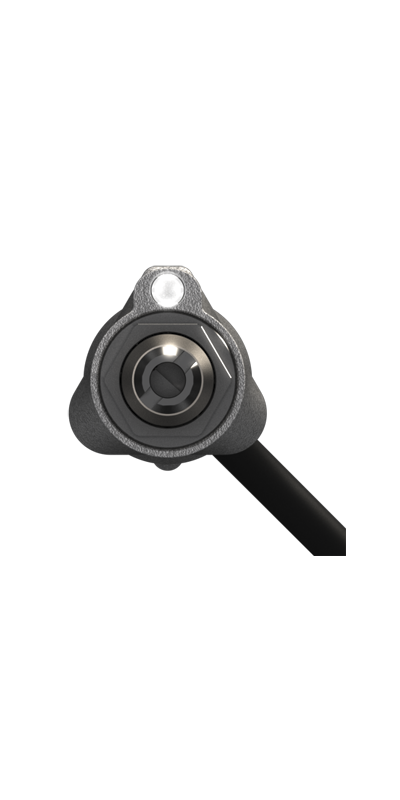

DS 34‑P series

Pistol grip nutrunner with electronically controlled servo motor and digital data transmission. Available in the torque variants 2.5 Nm, 5 Nm, 10 Nm and 15 Nm.

- Status indication via illuminated field

- Motor and gear are integrated in an aluminium housing

- Pistol handle

- Start switch and programmable function switch

- Adjusting wheel for speed limitation

- Suspension clip

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via digital absolute encoder

- Angle resolution: 0.1°

SA design

- Torque measurement indirectly via current cut-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 3,3° (DS34/05); 1,7° (DS34/10, 34/15)

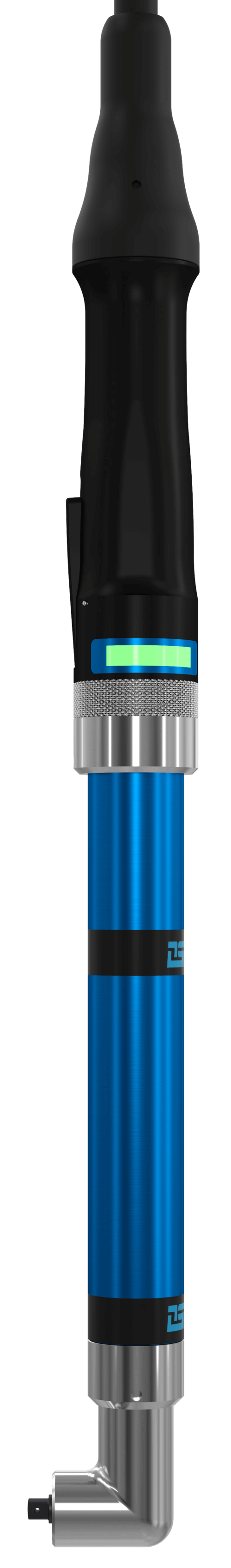

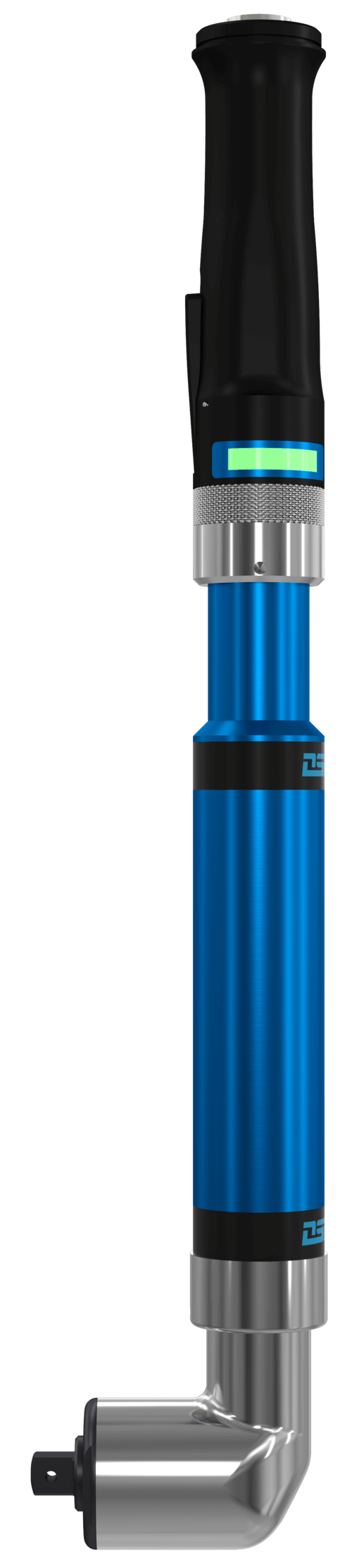

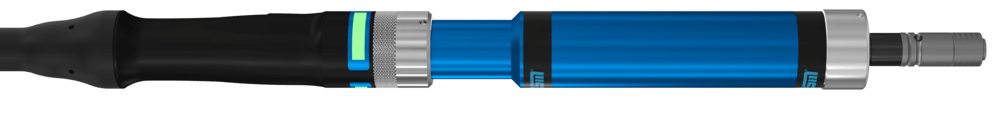

DSH 34 series

Hand-held nutrunner with electronically controlled servo motor and digital data transmission. Available with straight output in the torque variants 5 Nm and 10 Nm as well as with angle head in the variants 5 Nm, 10 Nm and 20 Nm.

- Illuminated field to indicate the tightening status

- Motor and gear are integrated in a robust housing

- Ergonomic handle

- Start button and programmable switchover ring

- Suspension / Suspension clip

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 1.7° (straight output); 1.2° (angle head)

SA design

- Torque measurement indirectly via current cut-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 1.7° (straight output); 1.2° (angle head)

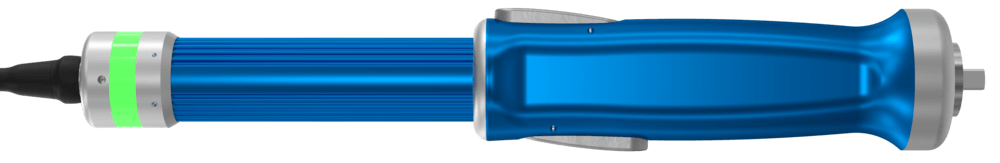

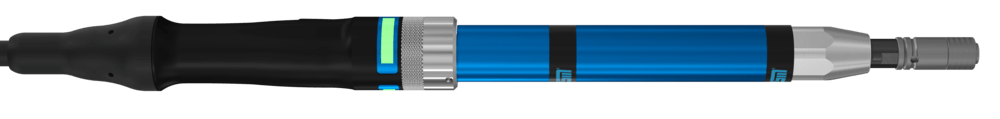

DSH 38 series

Hand-held nutrunner with electronically controlled servo motor and digital data transmission. Available in the torque variants 5 Nm, 10 Nm and 15 Nm.

- Illuminated field to indicate the tightening status

- Motor and gear are integrated in a robust housing

- Ergonomic handle

- Start button and programmable switchover ring

- Headlights for illumination of the application

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 0.01°

- Speed max. 1540 rpm

DS 44‑P series

Pistol grip nutrunner with electronically controlled servo motor and digital data transmission. Available in the torque variants 2.5 Nm, 5 Nm, 10 Nm, 20 Nm and 35 Nm.

- Status indication via illuminated field

- Motor and gear are integrated in an aluminium housing

- Pistol handle

- Start switch and programmable function switch

- Adjusting wheel for speed limitation

- Suspension clip

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via digital absolute encoder

- Angle resolution: 0.1°

SA design

- Torque measurement indirectly via current cut-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 3,3° (DS44/05); 2,3° (DS44/10); 1,4° (DS44/20); 1,0° (DS44/35)

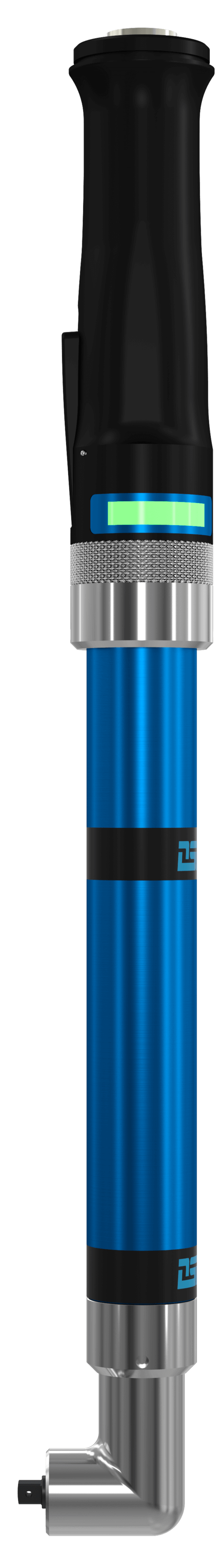

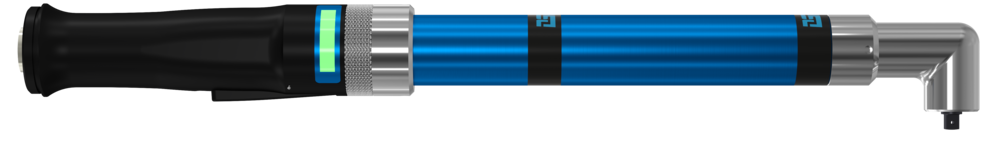

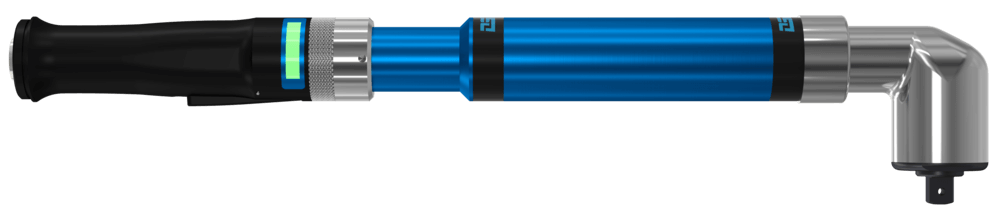

DSH 44 series

Hand-held nutrunner with electronically controlled servo motor and digital data transmission. Available with straight output in the torque variants 20 Nm and 30 Nm as well as with angle head in the variants 40 Nm and 60 Nm.

- Illuminated field to indicate the tightening status

- Motor and gear are integrated in a robust housing

- Ergonomic handle

- Start button and programmable switchover ring

- Suspension / Suspension clip

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 1.0°

SA design

- Torque measurement indirectly via current cut-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 1.0°