Press-in technique

The XMP Series

Maximum Modularity for Your Assembly Processes

The XMP press-in units are built modularly from standardized components – ideal for customized configurations, from simple joining tasks to complex assembly or testing applications.

Whether pressing or pulling forces, redundant force sensors, individually matched gear modules, or additional brake elements: the XMP series can be precisely tailored to your requirements.

Highly precise force sensors, absolute stroke measurement, and integration with the MultiPro 3G control system ensure maximum accuracy and seamless documentation.

Alternatively, the XMP series is also available in a current-controlled SA version without a force sensor – providing an economical solution for simpler press-in tasks.

A large integrated light field visually supports the operator by displaying process status, direction of movement, and current position.

With the XMP series, you get a future-proof solution for quality-critical assembly and testing processes – flexible, functional, and precise.

Technical Features at a Glance:

-

Gear modules for process-adapted feed speeds

-

Optional attachment of a customer-supplied motor

-

Available with motor holding brake, mechanical holding brake, or backstop

-

Force sensor available for different force ranges, also in redundant version

-

Absolute stroke measurement system for precise position detection

-

Large light field to display process status, direction of movement, and plunger position

- Optional: multi-range calibration for various force ranges

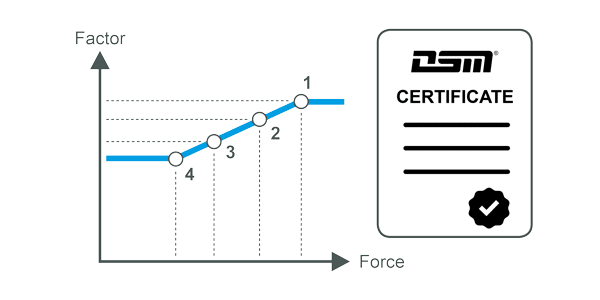

Multi-Range Calibration

With the optional multi-range calibration, you can flexibly use your press-in unit for applications with varying force requirements – while maintaining consistently high measurement accuracy.

Especially for frequently changing processes or component variants, calibration across multiple defined measurement points ensures reliable and precise results throughout the entire force range.

🔧 How it works:

Up to five measurement points are defined via a calibration series using a reference transducer. This allows force measurement to be specifically adjusted to different force levels within the press-in unit’s operating range – for maximum precision from low to high forces

Select a Series

for More Information:

0.1 – 2.0 kN (3 versions)

1 – 25 kN (3 versions)

6 – 100 kN (4 versions)

🔍 XMP BenchPressUnit:

Modular workstation for press-in processes with XMP 60 and XMP 90 units – ergonomic, safe, and flexible.

Equipped with integrated safety technology for precise and process-secure operation.

Press-in unit with brushless, electronically controlled servo motor, absolute stroke measurement system, and a large illuminated field – available either with a digital force sensor or as a current-controlled SA version.

The XMP-60 series is available in a basic design with a stroke of 200 mm or 400 mm. Nominal forces of 0.5 kN, 1 kN, and 2 kN are available – in DR version (compression) or DZ version (compression and tension).

Features

- Servo motor, motor attachment via motor offset for a short design

- Force measurement in compression direction – sensor-controlled or current-controlled (SA); tension and compression option only available with force sensor version

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

Gear Module

- Gear module 4Z (to max. 2 kN), Stamping speed max. 400 mm/s in both directions continuously variable

Force Sensor Control Type

- KU: Force sensor bottom, integrated in the plunger; Precision of force measurement 0.5% of the final value

- RU: Redudant force sensor bottom, integrated in the plunger; Precision of force measurement 0.5% of the final value

SA Control Type (without force sensor)

- Indirect force measurement via current-controlled shut-off

- Force accuracy depends on the adjustment of the press-in unit – calibration through reference measurement and configuration on the MultiPro 3G

- Regular reference measurements ensure accuracy

- Cost-effective solution for simple press-in tasks

Force Ranges

- XMP 60 / 005: 0.1 – 0.5 kN

- XMP 60 / 01: 0.2 – 1 kN

- XMP 60 / 02: 0.4 – 2 kN

Standard Options

- Calibration of the force sensor for tension and compression force measurement (DZ) – only for versions with force sensor

Accessories

- Fan unit for cooling the motor

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set

Dimensions and Weight

Dimensions (W × D × H):

- 60 × 142 × 572 mm (200 mm stroke)

- 60 × 142 × 772 mm (400 mm stroke)

Weight:

- approx. 8 kg (200 mm stroke)

- approx. 10 kg (400 mm stroke)

Press-in unit with brushless, electronically controlled servo motor, absolute stroke measurement system, and a large illuminated field – available either with a digital force sensor or as a current-controlled SA version.

The XMP-90 series is available in a basic design with a stroke of 200 mm or 400 mm. Nominal forces of 5 kN, 12.5 kN, and 25 kN are available – in DR version (compression) or DZ version (compression and tension).

Features

- Servo motor, motor attachment via motor offset for a short design

-

Force measurement in compression direction – sensor-controlled or current-controlled (SA); tension and compression option only available with force sensor version

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

Gear Module

- Gear module 4Z (to max. 25 kN), Stamping speed max. 200 mm/s in both directions continuously variable

- Gear module 2Z (to max. 12,5 kN), Stamping speed max. 400 mm/s in both directions continuously variable

- Gear module 1Z (to max. 5 kN), Stamping speed max. 900 mm/s in both directions continuously variable

Force Sensor Control Type

- KU: Force sensor bottom, integrated in the plunger; Precision of force measurement 0.5% of the final value

- RU: Redudant force sensor bottom, integrated in the plunger; Precision of force measurement 0.5% of the final value

SA Control Type (without force sensor)

-

Indirect force measurement via current-controlled shut-off

-

Force accuracy depends on the adjustment of the press-in unit – calibration through reference measurement and configuration on the MultiPro 3G

-

Regular reference measurements ensure accuracy

-

Cost-effective solution for simple press-in tasks

Force Ranges

- XMP 90 / 05: 1 – 5 kN

- XMP 90 / 12.5: 2.5 – 12.5 kN

- XMP 90 / 25: 5 – 25 kN

Standard Options

-

Calibration of the force sensor for tension and compression force measurement (DZ) – only for versions with force sensor

- Motor holding brake for higher tool weight as well as in combination with backstop for braking the movement.

- Holding brake – blocks the drive moving in and out (holding time max. 999 s), i.e. to move the plunger of the press-in unit, the brake must be switched off.

- Backstop – blocks the drive only when moving in (holding time as long as desired). Due to the mechanical design (free-wheel, almost backlash-free), the plunger is inhibited against “pushing in” in any position and can thus hold a counterforce. The permanent holding of the set force is guaranteed by the regulation by means of the stepper motor control.

Accessories

- Fan unit for cooling the motor

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set

Dimensions and Weight

Dimensions (W × D × H):

- 90 × 193 × 592 mm (200 mm stroke)

- 90 × 193 × 792 mm (400 mm stroke)

Weight:

- approx. 27 kg (200 mm stroke)

- approx. 40 kg (400 mm stroke)

Press-in unit with brushless, electronically controlled servo motor, absolute stroke measurement system, and a large illuminated field – available either with a digital force sensor or as a current-controlled SA version.

The XMP-120 series is available in a basic design with a stroke of 200 mm or 400 mm. Nominal forces of 30 kN, 50 kN, 75 kN, and 100 kN are available – in DR version (compression) or DZ version (compression and tension).

Features

- Servo motor, motor attachment via motor offset for a short design

-

Force measurement in compression direction – sensor-controlled or current-controlled (SA); tension and compression option only available with force sensor version

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

Gear Module

- Gear module 3Z + Motor 1M (to max. 30 kN), Stamping speed max. 500 mm/s in both directions continuously variable

- Gear module 3Z + Motor 2M (to max. 50 kN), Stamping speed max. 320 mm/s in both directions continuously variable

- Gear module 5Z + Motor 1M (to max. 50 kN), Stamping speed max. 270 mm/s in both directions continuously variable

- Gear module 5Z + Motor 2M (to max. 100 kN), Stamping speed max. 170 mm/s in both directions continuously variable

Force Sensor Control Type

- KU: Force sensor bottom, integrated in the plunger; Precision of force measurement 0.5% of the final value

- RU: Redudant force sensor bottom, integrated in the plunger; Precision of force measurement 0.5% of the final value

SA Control Type (without force sensor)

-

Indirect force measurement via current-controlled shut-off

-

Force accuracy depends on the adjustment of the press-in unit – calibration through reference measurement and configuration on the MultiPro 3G

-

Regular reference measurements ensure accuracy

-

Cost-effective solution for simple press-in tasks

Force Ranges

- XMP 120 / 30: 6 – 30 kN

- XMP 120 / 50: 10 – 50 kN

- XMP 120 / 75: 15 – 75 kN

- XMP 120 / 100: 20 – 100 kN

Standard Options

-

Calibration of the force sensor for tension and compression force measurement (DZ) – only for versions with force sensor

- Motor holding brake for higher tool weight as well as in combination with backstop for braking the movement. The motor version 2M is equipped with a motor holding brake.

- Holding brake – blocks the drive moving in and out (holding time max. 999 s), i.e. to move the plunger of the press-in unit, the brake must be switched off.

- Backstop – blocks the drive only when moving in (holding time as long as desired). Due to the mechanical design (free-wheel, almost backlash-free), the plunger is inhibited against “pushing in” in any position and can thus hold a counterforce. The permanent holding of the set force is guaranteed by the regulation by means of the stepper motor control.

Accessories

- Fan unit for cooling the motor

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set

Dimensions and Weight

Dimensions (W × D × H):

- 120 × 250 × 834 mm (200 mm stroke)

- 120 × 250 × 1034 mm (400 mm stroke)

Weight:

- approx. 75 kg (200 mm stroke)

- approx. 90 kg (400 mm stroke)