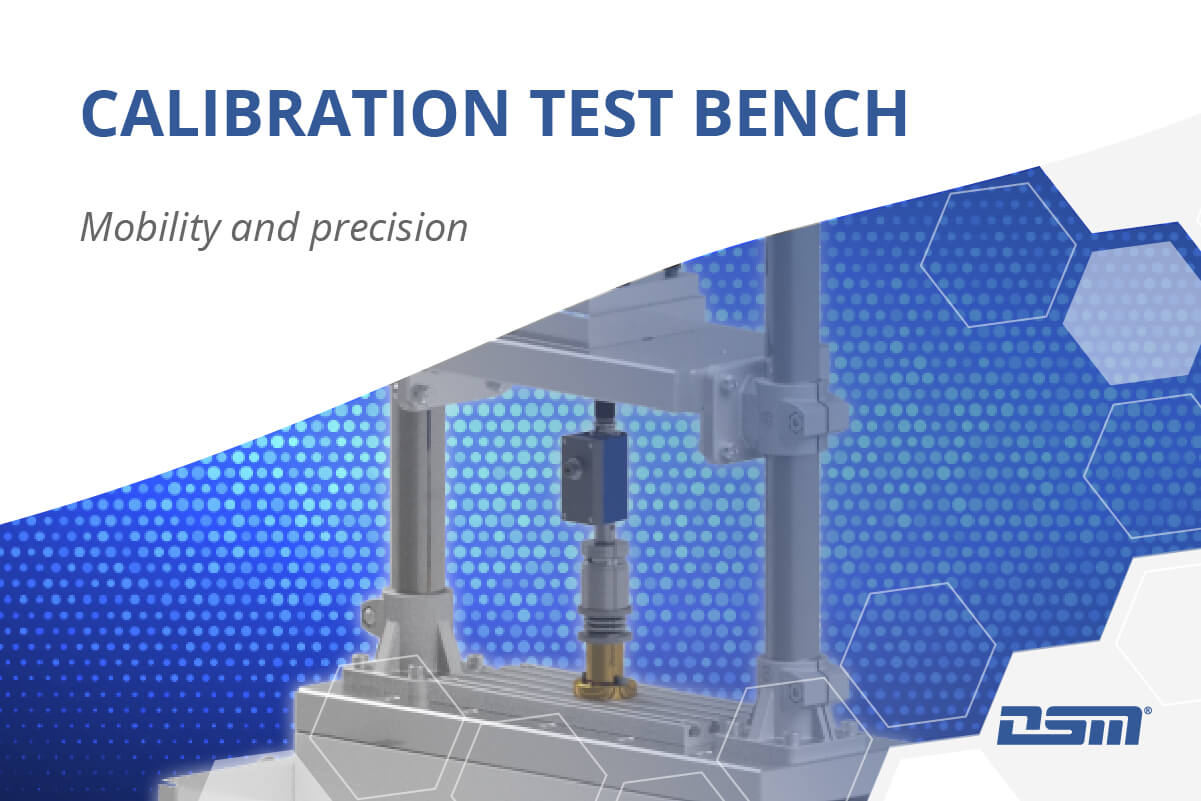

Precise calibration of Hand-held nutrunners DSH series and Built-in nutrunners DS series — maximum flexibility with our mobile test bench!

Mobile calibration test bench

Our robust calibration test bench offers the perfect solution for the precise testing and calibration of nutrunners with a torque up to 500 Nm.

Thanks to its flexible modularity, the assembly of Tightening Technology as well as third-party tools is effortless.

This test bench offers maximum versatility with specially adapted mounting plates for each size and thumb nuts for secure fastening.

Tool clamps ensure additional fixation of the nutrunner. The tightening simulator is attached to the base plate.

The height can be easily adjusted with the handwheel, depending on the configuration of the simulator and the installation size of the reference measuring sensor.

Maximum flexibility

Our mobile calibration test bench can be easily positioned on the floor, on a workbench, or on a transport trolley without the need for time-consuming assembly. The foldable stand ensures additional stability and enables safe use.

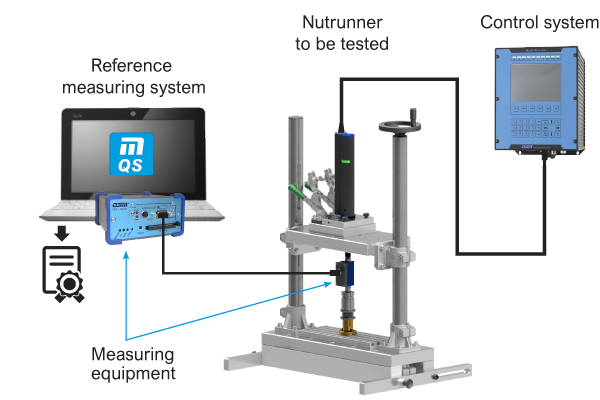

QS box digital measuring system

The QS box digital measuring system from DSM offers an effective solution for the calibration of nutrunners.

The combination of QS box, a suitable torque sensor and the MQS software ensures a comprehensive measurement procedure.

Each measurement is carried out on the basis of the information entered about the measuring equipment, the nutrunner to be tested and the defined measurement parameters. The software not only conducts measurements but also serves for displaying the measured values and conducting analyses.

This analysis function enables a thorough evaluation of the measurement results in order to identify any deviations or trends and take appropriate action.

With the digital measuring system from DSM, you get a reliable solution for calibrating nutrunners that not only works efficiently but also ensures a high level of accuracy and control over the measuring processes.

Data sheet

Here you will find the corresponding technical data sheet for our mobile calibration test bench with the available equipment variants. You can view or download the document directly in the browser.

Frequently Asked Questions (FAQ)

1. What is a mobile calibration test bench?

A mobile calibration test bench is a portable system designed to calibrate hand-held and built-in nutrunners directly on-site, eliminating the need to send tools to external laboratories.

2. What are the advantages of using a mobile calibration test bench?

It reduces downtime, saves transportation costs, and allows for calibration under actual working conditions, ensuring greater accuracy and efficiency.

3. Which types of nutrunners can be calibrated with this bench?

The bench is suitable for calibrating various models of hand-held and built-in nutrunners, including those from the DSM DSH and DS series, with torque ranges up to 500 Nm.

4. How does the calibration process work?

The nutrunner is mounted on the test bench and connected to a torque sensor; the system then measures and compares the output against predefined standards to ensure accuracy.

5. Is the mobile calibration test bench compatible with third-party tools?

Yes, its modular design and adaptable mounting plates allow for the calibration of nutrunners from various manufacturers, not just DSM products.

6. Can the test bench be integrated into existing production lines?

Absolutely; its compact and flexible design enables seamless integration into current workflows without significant modifications.

7. What documentation is provided after calibration?

A detailed calibration report is generated, documenting all measurements and ensuring traceability in compliance with quality management standards.

8. How often should nutrunners be calibrated?

Calibration frequency depends on usage intensity and quality requirements, but a regular schedule—such as annually or after a set number of cycles—is recommended to maintain precision.

Note: This FAQ is intended for general informational purposes and does not replace personalized advice. For specific inquiries, please consult a qualified specialist.